Manuscript accepted on :05-08-2022

Published online on: 25-08-2022

Plagiarism Check: Yes

Reviewed by: Dr. Sharad Kamble

Second Review by: Dr. Niharika Kondepudi

Final Approval by: Dr. H Fai Poon

Reda Hallab1* , Khalida Eddaoui2 and Nouzha Ben Raïs Aouad2

, Khalida Eddaoui2 and Nouzha Ben Raïs Aouad2

1Doctoral Study Center for Life and Health Sciences, Faculty of Medicine and Pharmacy of Rabat, Impasse Souissi, Rabat 10100, Morocco.

2Nuclear Medicine Department, IBN SINA Hospital - Ibn Sina Rabat University Hospital Center, Avenue Abderrahim Bouabid, Rabat

Corresponding Author E-mail: reda_hallab@um5.ac.ma

DOI : https://dx.doi.org/10.13005/bpj/2497

Abstract

Quality assurance generally refers to the measures taken to ensure that equipment meets international requirements and recommendations. PET/CT quality control is based on measures used to regularly monitor the performance of the installed imaging equipment in terms of image quality and dose and to ensure effective radiation protection. Indeed, the objective of this study is to evaluate the daily quality control, used on of the Positron Emission Tomography “PET” part of the “PET/CT”, after one year without daily quality control knowing that the medical physicist is not present in the institution. Material and methods, it was used the “PET/CT” equipment of the nuclear medicine department of a hospital, and the PET part, the Germanium 68 (Ge-68) source for “QC”, and a questionnaire related to quality assurance and radiation protection distributed in the said department. Results of this study, after the “QC” of the “PET”, some problems were identified; the correction of the defective modules was performed, and answers were collected from the distributed questionnaires. For the discussion, the absence of implementation of a quality assurance program in the nuclear medicine department, including the establishment of daily quality control procedures and radiation safety training, was attributed to the inexistence of a qualified medical physicist, referring to the questionnaire responses. To conclude, quality assurance in a nuclear medicine department and daily quality control of the “PET”, as well as the existence and control of a qualified medical physicist for medical activities with ionizing radiation sources, ensure optimal patient radiation protection.

Keywords

Daily quality control; Medical physicist; Nuclear Medicine; Quality assurance - PET/CT

Download this article as:| Copy the following to cite this article: Hallab R, Eddaoui K, Aouad N. B. R. The Quality Assurance for the PET/CT in Nuclear Medicine - Evaluation of the Daily Quality Control of The Positron Emission Tomography. Biomed Pharmacol J 2022;15(3). |

| Copy the following to cite this URL: Hallab R, Eddaoui K, Aouad N. B. R. The Quality Assurance for the PET/CT in Nuclear Medicine - Evaluation of the Daily Quality Control of The Positron Emission Tomography. Biomed Pharmacol J 2022;15(3). Available from: https://bit.ly/3TeVgGu |

Introduction

Generally, clinical radionuclide counting and imaging instruments in nuclear medicine depend on a certain level of accurate and reproducible performance1. Furthermore, by international standards and recommendations, the quality assurance program should include “QC” procedures. These must be performed on a regular and planned basis, by applicable requirements established by regulatory bodies2. Indeed “QC” is defined as an essential part of routine nuclear medicine practice. However, over the years many parameters for acceptability testing and performance characterization of the “PET/CT”, and other nuclear medicine instruments have been developed. To this end, various associations, regulatory, advisory, and professional organizations (American Association of Physicists in Medicine “AAPM”, International Atomic Energy Agency “IAEA”, American Society of Radiology “ACR”, and others) have published detailed data collection and analysis methods1. “PET/CT” plays an essential role in oncology for diagnosis and follow-up, it is essential to check the equipment regularly, especially for consistency and coincidence, as well as maximum energy through “QC” procedures3, 4. This technique will continue to play an important role in precision nuclear medicine (4). Indeed, the purpose of “PET” daily quality control is to ensure consistency of detector functionality and to identify any problems, such as a crystal or module failure5. The procedure is performed using a phantom with a Ge-68 source in a cylindrical form in most cases to ensure optimal crystal performance3, 5, 6, 7. In addition, the purpose of daily quality control is to correlate the data from the sinograms; sinogram control (uniformity) is obtained daily using a Ge-68 source to the values determined during system calibration, for this the recalibration is required if the differences exceed the tolerance levels8.The main daily quality control steps related to the operating parameters of the detector are coincidence detection, singles, dead time, timing, and energy resolution9.

One of the main roles and responsibilities of the qualified nuclear medicine physicist is to ensure optimization of the physical aspects of the diagnostic procedure. This task is performed in collaboration with other qualified medical staff 10. The qualified medical physicist must establish a quality assurance program that will include daily quality control procedures for the equipment in the department that uses ionizing radiation for medical protocols. Personnel of the department should consult with a qualified medical physicist if measured values of daily quality control parameters exceed established tolerances. However, corrective actions should be prescribed to resolve problems raised during daily quality control11.In addition, a technologist should perform the daily quality control, and it is recommended that these procedures be performed before the clinical use of the scanner7, 12.

Daily quality control for General Electric Discovery “GE. D” equipment – “PET/CT”:

An integrated Ge-68 source in the scanner’s field of view is required for daily quality control of “GE. D” equipment “PET/CT”; the source is not visible because it is located behind the scanner enclosure9. As mentioned above, the daily quality control of the “PET” is performed sequentially and evaluates coincidences, singles, timeouts, timing, and system energy. A visual and parametric data report on the status of the detectors in the form of an image “sinogram” (Figure.1) after the “PET” daily quality control procedure is completed. A scale of three represents the parametric results obtained during the procedure: green indicates a setting that is within an acceptable range, yellow indicates a recommended setting and red indicates a setting that is outside an acceptable range13.

|

Figure 1: Example of Sinogram of daily “PET” – “QC” Ge Discovery Technology13 |

The following table provides recommendations for the daily quality control procedures that should be scheduled and performed for the “PET/CT”. The purpose of the procedure, the frequency, and comments on the procedure, the type of technology, and the parameters of “QC” are performed in (Table. 1)14. In addition, the manufacturer sets the parameters and frequency of “QC” tests for each “PET/CT” system that each qualified medical physicist should follow to perform a control procedure within the standards15.

Table 1: Daily quality control for “PET” – GE systems14, 15

| Control | Type of Technology | Purpose | Frequency | Comments |

QC parameters

|

| PET Daily QC | GE Systems | Visualize the operation of the detection modules.

A display of a sinogram |

Daily | Performed with point sources (Source of Ge-68) |

Coincidence test Singles test Energy test Timing test Deadtime test

|

In effect, the objective of this study is to evaluate the “PET” daily quality control in a nuclear medicine department, of the “PET” to the “PET/CT” equipment, after one year without a daily control procedure in the absence of a qualified medical physicist in the department.

Materials and Methods

The equipment of this study, especially for the daily quality control has a “PET/CT” (GE. Discovery 610 Elite, USA), which is composed of a computed tomography part and a “PET” part, using crystals of (Bismuth Germanate – BGO). A Ge-68 source was used as recommended for this control. Before the start of the “QC”, a questionnaire on the quality assurance program was distributed to the medical staff of the nuclear medicine department to collect responses. Our method is as follows, in the absence of a qualified physicist in the nuclear medicine department, the biomedical engineer of the “PET/CT” manufacturer started the daily quality control procedure after one year without “QC”, a report was displayed on the console of the “PET/CT”; sinogram 1; the procedure lasted 11 minutes; (Figure 2). The procedure displayed two errors concerning two modules of the “PET” – crystal scintillator, the object of our work.

|

Figure 2: Sinogram of daily quality control for the (PET)-GE Discovery 610 Elite (study). |

Following our method of “QC”, the biomedical engineer launched a roadmap (workflow of the process of calibration of the detector) (Figure 3), to remedy the errors found and perform corrective actions, parameters that refer to the recommendation of the manufacturer. The gain than the energy step (Figure 4) reflects the peak energy spectrum for each PET crystal16, finally, the timing of each crystal which showed the illustration of a failed module (Figure 5).

|

Figure 3: Roadmap (detector calibration process workflow) -GE Discovery 610 Elite (study). |

|

Figure 4: Energy step –Roadmap of the (QC) (PET). |

|

Figure 5: Timing step – Roadmap of the (QC) – (PET). |

However, the questionnaire that was distributed to the staff of the nuclear medicine department focused on the following aspects (training in radiation protection for patients and the implementation of the quality assurance program especially the “QC” procedures in the nuclear medicine department.

Results

At the end of the “QC” procedure, a final report in the form of a sinogram was resulted (Figure 6). Indeed, a positive result, because the failure of the module noted at the beginning of the control, was corrected through the correctives actions performed by the daily quality control procedure especially the steps of the roadmap.

|

Figure 6: Corrected sinogram – Daily quality control for the (PET – GE discovery 610 elite (study). |

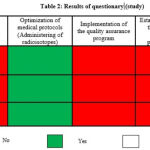

In addition, according to the results collected from the questionnaire previously distributed to the medical staff of the department of nuclear medicine; object of our work; the staff does not have optimal training in radiation protection for patients in addition to the lack of implementation of a quality assurance program and specifically the establishment of “QC” procedures. The results of the questionnaires distributed reflect in (Table 2).

|

Table 2: Results of questionary (study). |

Discussion

According to the result of the “QC”, a procedure performed for the “PET/CT”, object of our this study, in particular the corrective actions of a failing module of the “PET”, it is important to perform the “QC” with the daily frequency for the GE equipment13,14,15.In addition, according to the results of the questionnaire distributed to the staff of the nuclear medicine department (nuclear medicine physicians, technologists, and nurses), the implementation of a quality assurance program is absent specifically the realization of “QC” procedures, as well as the establishment of training in radiation protection of the patient, particularly continuous training in the department. Two fruitful results of this study demonstrate the importance of a qualified medical physicist within a nuclear medicine department using ionizing radiation. First, he will ensure the implementation of a quality assurance program11and the establishment of the “QC” procedures that represent an essential step of the said program2. The procedures will be performed by the “PET/CT” unit technologist and consulted with a qualified medical physicist11, 17. Second, he assists in the implementation of training in radiation protection of the patient in the unit, which is also among the steps of the quality assurance program2.Moreover, it is an important study that affirms the usefulness of the presence of a qualified medical physicist, in particular, a requirement that described the law 142-12 in article 102; at least one qualified medical physicist must be present in each nuclear medicine department18. Indeed, a study that will strengthen the academic opinion in Morocco in this field.

Conclusion

To conclude this successful study, it is necessary to establish a quality assurance program and implement the culture of radiation safety to ensure patient radiation protection in a nuclear medicine department2. Indeed, a quality assurance program should be implemented and should include the procedure for daily quality control of “PET/CT”, including the “PET” part13.In addition, the presence of a qualified medical physicist becomes essential in the nuclear medicine department, to ensure the establishment of daily quality control procedures and to implement radiation safety recommendations through radiation protection training for the patient. A work that will be in collaboration with the staff of the said department11.Therefore, it is important to evaluate the daily quality control parameters and take appropriate corrective actions2 and effective “QC” is an important means of ensuring the repeatability of medical applications19. To this end, it is made necessary to perform the said in each medical installation through the sources of ionizing radiation20, thus ensuring optimization of medical exposures and improved image quality for medical protocols in nuclear medicine.

Acknowledgement

I thank all the contributors who helped me in this work; Khalida Eddaoui, Pr. Nouzha Benraiss Aouad

I am asking for some of your precious time to inform you of the submission of my scientific article, to participate in the development of medical science in general and nuclear medicine in particular.

It will be a great pleasure and a great honor for me to publish in your prestigious journal.

Pending a favorable response, please accept, dear organizers, the expression of my sincere thanks.

Conflict of Interest

All authors declare that there is no conflict of interest

Funding Source

I declare that there are no sources of funding for this research study.

References

- Kheruka S. C. Importance of quality control in nuclear medicine. International Atomic Energy Agency (IAEA). INIS Volume 52. INIS Issue 23, 2020;

- Hallab R, Eddaoui khalida, Ouabi H, Raïs Aouad NB. Regulatory Requirements of Quality Assurance Program in Nuclear Medicine – Review of the Procedures. Biomedical and Pharmacology Journal. 2021 Dec 30;14(4):1863–7;

CrossRef - Vyas M, Tafti D. Nuclear Medicine Quality Assurance. [Updated 2022 Feb 5]. In: StatPearls [Internet]. Treasure Island (FL): StatPearls Publishing; 2022 Jan. Available from: http://https://www.ncbi.nlm.nih.gov/books/NBK576382/?report=reader.

- Schaefferkoetter JD, Osman M, Townsend DW. The Importance of Quality Control for Clinical PET Imaging. Journal of Nuclear Medicine. Technol. 2017 Dec;45(4):265–6 ;

CrossRef - Boellaard R, Delgado-Bolton R, Oyen WJG, Giammarile F, Tatsch K, Eschner W, et al. FDG PET/CT: EANM procedure guidelines for tumor imaging: version 2.0. European Journal of Nuclear Medicine and Molecular Imaging. 2015 Feb;42(2):328–54;

CrossRef - Zanzonico P. Routine Quality Control of Clinical Nuclear Medicine Instrumentation: A Brief Review. Journal of Nuclear Medicine. 2008 Jul;49(7):1114–31;

CrossRef - Dondi, M. and all. Quality assurance for PET and PET/CT systems. Vienna: International Atomic Energy Agency; 2009. (IAEA human health series) ;

- Saha GB. Basics of PET Imaging [Internet]. New York, NY: Springer New York; 2010 [cited 2022 Mar 1]. Available from: http://link.springer.com/10.1007/978-1-4419-0805-6;

- Claudiu P, Quality Control of Nuclear Medicine Instrumentation and Protocol Standardisation. European Association of Nuclear Medicine.Vienna, Austria, 2017;

- Pasawang P, Sontrapornpol T, Krisanachinda A. EXPERIENCE ON PERFORMANCE MEASUREMENTS OF POSITRON EMISSION TOMOGRAPHS, Medical Physics International Journal, vol.7, No.3, 2019;

- ACR–AAPM Technical Standard For MEDICAL PHYSICS PERFORMANCE MONITORING OF PET/CT IMAGING EQUIPMENT, (CSC/BOC), 2018, The American College of Radiology;

- Hacıosmanoğlu T, Demir M, Toklu T, Kıraç FS, İnce M, Parlak Y, and all. Acceptance Tests and Quality Control of the Positron Emission Tomography (PET) Systems. Nuclear Medicine Seminar. 2020 Aug 26;6(2):51–70;

CrossRef - Andersen, F. and all. PET/CT atlas on quality control and image artefacts. — Vienna: International Atomic Energy Agency, 2014,(IAEA human health series, ISSN 2075–3772 ; no. 27) ;

- Busemann Sokol E, Płachcínska A, Britten A, Lyra Georgosopoulou M, et al. Routine quality control recommendations for nuclear medicine instrumentation. European Journal of Nuclear Medicine and Molecular Imaging. 2010 Mar;37(3):662–71;

CrossRef - Lopez BP, Jordan DW, Kemp BJ, Kinahan PE, Schmidtlein CR, Mawlawi OR. PET/CT acceptance testing and quality assurance: Executive summary of AAPM Task Group 126 Report. Med Phys [Internet]. 2021 Feb [cited 2022 Mar 1];48(2). Available from: https://onlinelibrary.wiley.com/doi/10.1002/mp.14656;

CrossRef - Mawlawi OR, Jordan DW, Halama JR, Schmidtlein CR, Wooten WW. PET/CT Acceptance Testing and Quality Assurance.The Report of AAPM Task Group 126. 2019 Oct.;

CrossRef - Hristova I, Boellaard R, Galette P, Shankar LK, Liu Y, Stroobants S, et al. Guidelines for quality control of PET/CT scans in a multicenter clinical study. European Journal of Nuclear Medicine and Molecular Imaging Physics. 2017 Dec;4(1):23 ;

CrossRef - Government of Kingdom of Morocco. Law 142-12, Related to Nuclear and Radiological Safety and Security and the Creation of Moroccan Agency for Nuclear and Radiation Safety and Security. 2014;

- He Z, Hou L, Sun R, Yin T, Ma P, Chen L, et al. The Status of the Acupuncture Mechanism Study Based on PET/PET-CT Technique: Design and Quality Control. Evidence-Based Complementary and Alternative Medicine. 2019 Nov 29; 2019:1–8;

CrossRef - Swarna SK, Nivedhitha MS. Awareness of Radiation protection protocols among General practitioners and Endodontists in Chennai-A Cross-sectional questionnaire-based survey. Research Journal of Pharmacy and Technology. 2020;13(1):81.

CrossRef