Manuscript accepted on :27-06-2020

Published online on: 16-07-2020

Plagiarism Check: Yes

Reviewed by: Bhavana Gundavarapu

Second Review by: Haider Mousa

Final Approval by: Dr. H Fai Poon

T. Sudhakar1 , G. Hari Krishnan2, G. Umashankar1, Sindu Divakaran1, U. Bhurnima1 and B. Shanchita1

, G. Hari Krishnan2, G. Umashankar1, Sindu Divakaran1, U. Bhurnima1 and B. Shanchita1

1Department of Biomedical Engineering Engineering, Sathyabama Institute of Science and Technology, Chennai, India

2Department of Electrical and Electronics Engineering, Sree Vidyanikethan Engineering College, Tirupati, India

Corresponding Author E-mail : haris_eee@yahoo.com

DOI : https://dx.doi.org/10.13005/bpj/1992

Abstract

Dispensaries and pharmaceuticals in Hospital today faces problem in retrieving of drugs. To overcome this problem, we introduced automatic retrieving of drugs using robot arm. In this project paper the robot will autonomously retrieve the medicines as per the command given. The robotic arm is carried in an Automatic Guided Vehicle for pick and place operations. Microcontroller and sensors are used to control the wheel movement. The robot arm is controlled by servos. By this method human error can be minimised and there will be no confusion in retrieving drugs.

Keywords

Arduino Uno; Drug Delivery; Microcontroller; Pharmaceutical; Robotic

Download this article as:| Copy the following to cite this article: Sudhakar T, Krishnan G. H, Umashankar G, Divakaran S, Bhurnima U, Shanchita B. Drug Retrieving System In Hospitals Using Robotics. Biomed Pharmacol J 2020;13(3). |

| Copy the following to cite this URL: Sudhakar T, Krishnan G. H, Umashankar G, Divakaran S, Bhurnima U, Shanchita B. Drug Retrieving System In Hospitals Using Robotics. Biomed Pharmacol J 2020;13(3). Available from: https://bit.ly/30elmyR |

Introduction

Today’s technology is mostly based on human needs. But humans cannot undergo all work in this busy world. To save human time and to make easy operation of task robotic studies are implemented. Robots can do interdisciplinary work in all fields. It can be in any form in resembling human. In such cases instead of full robot we can use specified parts of robots. Like robotic arms which are used in manufacturing industries, lifting things, mixing of hazardous substances etc… In our project we are introducing a robot arm for automatic retrieving of drugs and medicines [1]. An automated retrieval system can be defined as pick and place of these drugs at defined degree of automation to ensure precision accuracy and speed [2]. This retrieving process is done autonomously where the arm will move based on the commands or key codes loaded on the computer [3 & 4].

For this we don’t need any guide to move along with it. In our paper we are going to retrieve drugs in pharmacies and hospital dispensaries [5 & 6]. Because in those areas there will be lot of drugs and medicines when a human is working on it there will be lot of confusion, misplacing of medicines can happen, while delivering they can give wrong medicines, they can forget the exact place where it is located. To overcome these problems we have introduced a robot arm to retrieve drugs automatically without man power [7 & 8]. This process can be easily done loading the medicines and drugs names where and which place and rack they have kept in the shelf. So for that each one we assigned particular key codes. When we command that key code it will bring and go back and replace the drug in respective places. By this process human error is avoided [9 & 10].

Automatic Guided Vehicle (AGV) is a robot that moves according to the command given in it. They are most often used in hospital dispensary and medical shops to pick and place the medicines.

AGV to be used here will be moves on aluminium beading which chooses a path

The 2nd and 3rd servos rotate from 0 to 180. If servo2 is 0 servo 3 is 180. The same for oppositely applied when servo2 is 180 servo3 is 0.It is connected to the 1stservo with a rotational joint.

The 4th servo decides the position for forward and backward motion.

The 5th servo connected with end effector will picks and places the drugs.

The 4th and 5th servos take the position and fix the height for retrieving process into and out of the shelves.

The robot arm is designed with 4 DOF and programmed to lift light material to assist in production line in any industry [11 & 12]. 3D-Printing method is used for easy fabrication in proper dimensions and cost-saving. 4 servos are linked to bring the movements. Open source hardware and software are used and it is done wireless. The wireless motion is controlled using smart phones through Bluetooth module.

Aimn Mohamed Admed Ghiet (2017) had said that the robot works by picking and placing that is carrying the materials from the one place to another place and also mixes the materials it receives if needed. It contains 4 directions with 5 servo motors. It is done by connecting the robot with an Arduino application via Bluetooth module connected in Arduino Nano microcontroller [13 & 14].

Dobot robot arm: It has 4 axis and a Microsoft windows. The communication is done through Wi-Fi, Bluetooth and USB. It is used in many applications like Printing, Writing, 3D Cutting, Welding, Arm movements with EMG signals like if we move our arm it will move accordingly, and mixing of materials and substances. Mathieu Beilanger – Barette(2015), constructed a Dual-Arm resembles like humans ways of picking and placing using suction cups. Because there will be no damage. The robot is equipped with a 2-Finger 85 Adaptive Gripper, suction cups and a vision system. The other robot is equipped with another vision system, a bigger suction cup and some kind of platter. The arm has 3 DOF with extra 4 DOF attached with gripper that sucks the things from particular shelf [15 & 16].

Patel Charmin et al., (2015), had compared robot with human anatomy like shoulder and elbow joint and end of arm is called end effector which may be tool and its fixture or a gripper or any other device to work. Here loading and packing of lead batteries is been presented [17 & 18] used for picking and packing of bags, boxes, trays, pallets, syringe packaging, pharmaceutical tablet packaging etc.… They designed robot arms in different categories like polishing robots, welding robots, high-speed six axis robots, assembly robots, palletizing robots, painting robots, grinding robots, load and unload robots, picking and packaging robots, milling robots [19 & 20].

Tarun Agarwal, explained how a robot should be designed and constructed using 8051 microcontroller and motor drives. It is used in defence (Picking of harmful objects and diffuses safely), industrial (it is a machinery fixture. Picking and placing it in a conveyor belt) and medical (used in surgical operations) [21 &22].

Timothy Ndungu’s (2014), constructed a robot arm joints are automated by servo motor and they accessed Bluetooth capability [HC – 06]. They communicated from computer or phone and commands are given to move in prescribed positions [23 & 24]. Timol7, had designed using micro servos, cardboard sheets with pot. This pot controls the servos to fix in particular position. And operated using switches.

Amit Shelke, et al.,(2015),had proposed the robot arm for pick and place operations For gripping, lifting, placing and releasing. These are controlled with servo motors and ATmeg16.it has 6 DoF for independent movements. The end effector is controlled with the help of theoretical analysis of inverse kinematics [25 & 26].

Methodology

|

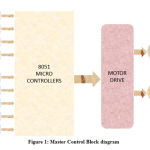

Figure 1: Master Control Block diagram |

The AGV will move in an aluminium beading in a given path. IR sensors (5 IR sensors are used) are placed on the nearby track where each sensor is placed in front of the particular shelves and a reset sensor is placed in a common place called the original position of the vehicle. These sensors are controlled using switches. There are 4 switches [S1-S3 & S5]. Switches S1, S2, S3 are assigned for particular Sensor 1, 2, 3. The return switch S5 is connected to the reset sensor which follows the original position of Port 7 of 8051 microcontroller. The motor drive is connected to Port 3[Port 3.0 – Port 3.3]. A common enable is given to +5V. Port 1 is connected to the switches to make the vehicle move to the following direction. Port1.0, 1.1, 1.2, and 1.3 are connected to switches. 12V battery is connected to power the motors. The robot arm is guided with Arduino programming. The robot arm is controlled using servo motors. 5-servo motors are used.

Servo 1 – Base – 1st DoF;

Servo2 & Servo 3 – 1st DoF;

Servo 4 – 2nd DoF;

Servo 5 – 3rd DoF.

And in the servo5 the end effector is placed for picking and placing. Common ground is connected to the 8051 microcontroller and +5V is also taken from 8051. From the SMPS cable ground and VCC are connected to the arm for each servo motors. The signal wire is connected to Arduino 2,3,4,5,6 pins. And the positioning, picking and placing is triggered automatically by the button state of Arduino A0, A1, A2 to the 8051 microcontroller Port 3.5, 3.6, 3.7 pins.

As the reset button is pressed in the 8051 the vehicle will come to the initial position till the sensor 4 (reset sensor) trigger. Now switch S1 is pressed, it makes the wheel to move in forward direction till the sensor 1 trigger and stops there. A pulse will be created within that time to initiate the arm to move. After it is created the arm will automatically turn around and picks the medicine, for this process a delay time of 8 secs is given and it will come back to the initial position until reset sensor is triggered. After we took the medicine return switch S5 is pressed and the vehicle will come to the sensor 1 till it triggered and places the medicine within the delay time. And come back to the initial position automatically. The same procedure is carried for other racks. Thus the robot autonomously retrieves the drugs.

|

Figure 2: IR Sensors Connections in Rail Track |

Tarun Agarwal designed a pick and place robot with the help of 8051 microcontroller and motor drivers. Where the whole construction is controlled by the microcontroller . They used H-bridge concept as shown in figure 1 in-cordially with the same concepts and the same components designed to move the wheels .The microcontroller and motor driver are connected only for vehicle motion. The Bo wheels and motors are used to give good speeds and accuracy .This makes the Bo motor to move in forward and backward direction which is preceded in the rail track.

Timol, Arduino Robot arm (TFCI). He used Arduino board for controlling the servo motors. With the help of potentiometer be controlled all the degrees of servos to fix it in the particular position. He triggered the position using switches. The servo coding is uploaded in Arduino UNO where the Arduino board is interfaced with 8051 microcontroller board as shown in figure 2. The assembly language program is coded such a way that it can automatically calls and triggers the robot arm by creating pulses within that delay time. When the pulses are passed the robot arm will automatically pick and place the medicines and drugs.

Results and Discussion

The IR sensors are connected to stop the vehicle we have implemented to stop the vehicle without pressing to stop the vehicle without pressing the switch we have implemented IR sensor which is an proximity sensor .It stops whenever any obstacle passes by the concept of IR sensor we have included it in our project. Switches are used for calling a particular sensor where the switch is pressed the vehicle goes and stops at the respective place when the sensor is triggered. A new concept is implemented to call the vehicle to that position.

|

Figure 3: Pick and place implementation |

In all papers and journals retrieving process by the same arm is not done. It is done separately. With a novel approach we used common switch to return to that spot and place the medicine as shown in figure 3. This research project was mainly aimed at developing a robotic arm for retrieving drugs and medicines in pharmacies and pharmaceuticals. Servos, sensors and motors are used to achieve this. The IR Sensors were placed in front of the each shelves and the servos are fixed on each joint of the arm. The motors are code in order to carry the arm to respective place. The movements are made like our normal human arm which contains 4 DOF in robotic arm.

The whole project took almost 7 months to complete. Initially, we surfed many websites and papers to get ideas about the microcontrollers, motors, wheel positioning and movements, software operations controlling servos and coding uses and how to operate and apply. With the reference of other arms we learned to design and fabricate the overall concept and finally designed and fabricated the whole project. Each component used is studied and are functioned. Simulation is done on real time in our design. The robot arm parts are joined together by fastener like screws and nuts. With the help of potentiometer we assigned the degrees for particular position the arm should operate for that code. The AGV is designed by normal other vehicle which contains 4 motor wheels B0 motors are used to give good accuracy and good timing and speed. 5 Servos are fixed in each degree of freedom at the joints. These servos have good strength to handle heavy objects and speed to retrieve. The IC’s and servos are checked multiple times to ensure safety of the components.

The hardware is designed and fabricated with acrylic board. This will withstand heavy weights. So that balancing the objects are made easier without any damage. The AGV and the robotic arm was made by acrylic board .As the vehicle carries the arm. The IR sensors were placed on a separate track in front of a particular shelf. As the switch is pressed the vehicle will stop when the respective sensor triggers others remains standby mode without responding.

The software i.e. coding is done in two different software’s .The wheel movement is guided with Keil software. Assembly language program is programmed and dumped into 8051 microcontroller. The robotic arm is coded using Arduino coding software where the servos are controlled. Finally they both are interfaced by giving time delay to the ASM program by that time the arm will retrieve the medicines. This process has undergone several trials on each step of processing. And the desired output is obtained at the final interfacing. Where the whole project will does its work autonomously with command given to the system. It will automatically retrieve’s the drug. Here human need is unnecessary except the billing section .The more trail and errors are conducted for verification .Finally, the desired output is obtained successfully.

Acknowledgement

The authors of this research work were thankful to Department of Biomedical Engineering, Sathyabama University and Centre for Energy, Sree Vidyanikethan Engineering College for providing needed support in all means.

Conflict of Interest

The six authors of this paper have no conflict of interest in any means.

Funding Source

We have not received any funding from any external or internal funding agencies. Funding for this research work has been contributed by self.

References

- Aimn Mohamed AdmedGhiet- “Robot arm control with Arduino”. June 2017. DOI:10.13140/RG:2.2.1027.53286.

- Amit Shelke, Manoj Botre, Ravikumar Mourya, Sourabh Satpute, Sushant Kakade, “Design and Implementation of Pick and Place Robotic Arm”, Vol.2,Issue1, April-September 2015, pp:232-240.

- Krishnan, G.H, Nanda, A., Natarajan, A. Synovial fluid density measurement for diagnosis of arthritis. BPJ 7(1), 221–224 (2014).

CrossRef - Anand, G. Krishna, G. Mohandass, R. Hemalatha, and S. Sundaram, “Predicting grade of prostate cancer using image analysis software,” in Trends in Inform. Sciences and Computing (TISC). IEEE, 2010, pp. 122–124.

CrossRef - Fumiko Beniyama , Kanako Esaki , Keisuke Fujimoto ,Kiyoto Ito ,Nobutaka Kimura, Oshio Moriya, Takki Fuji, Japan.“Mobile dual-arm robot for automated order picking system in warehouse containing various kinds of products. December 2015, 11-13.

- Ismail .M.A, Ismail. M.H, Mustaffa. N, QI.A.N.W, K.L.Voon, Malaysia, “Design and Development of a Mechanism of Robot Arm for Lifting Part1”, December 2015. . DOI:10.131.40/RG.2.1.4517.3845.

- Hari Krishnan, G., Ananda Natarajan, R., Nanda, A. Impact of upper limb joint fluid variation on inflammatory diseases diagnosis. JEET 9(6), 2114–2117 (2014).

CrossRef - Mathieu Beilanger – Barette, “Dual-Arm Warehouse Picking using Robotic Gripper” September 2015.

- Krishnan, G.H, Natarajan, R.A., Nanda, A. Comparative study of rheumatoid arthritis diagnosis using two different methods. BPJ 7(1), 379–382 (2014).

CrossRef - Krishnan, G.H., Natarajan, R.A., Nanda, A. “Microcontroller based non invasive diagnosis of knee joint diseases”, International Conference on Information Communication and Embedded Systems, ICICES 2014, 7034178 (2015).

CrossRef - Hari Krishnan, G., Abhinaya, N., Hemalatha, R.J., Mohandass, G., “Hardware implementation for feedback control based health monitoring and drug delivery”, Biomedicine(India), 37(1), pp.123-126 (2017).

- Nandhini, P., Hari Krishnan, G., Umashankar, G. Home based telemedicine system for respiratory disorder, International Journal of Pharma and Bio Sciences, 6(4), pp.8227-8231 (2015).

- Sudhakar, T., Hari Krishnan, G., Santosh, S., Meenakshi, S., Thomas, “Prosthetic arm control using processing device, a comparative approach”, Biomedical Research (India), 29(13), pp.2904-2907 (2018).

CrossRef - Mohandass, G., Ananda Natarajan, R., Hari Krishnan, G. Comparative analysis of optical coherence tomography retinal image using multidimensional and cluster methods. Biomedical Research(India), 26(2), pp.273-285 (2015).

- Nagarjuna Reddy, A., Hari Krishnan, G., Raghuram, D., “Real time patient health monitoring using raspberry PI, Research Journal of Pharmaceutical, Biological and Chemical Sciences, 7(6), pp.570-575 (2016).

- Hari Krishnan, G., Umashankar, G., Abraham, S., “Cardiovascular disorder diagnosis using MR angiography”, Biomedical Research(India), 27(3), pp.773-775 (2016).

- Krishnan, G.H., Natarajan, R.A., Nanda, A. “Microcontroller based non invasive diagnosis of knee joint diseases”, International Conference on Information Communication and Embedded Systems, ICICES 2014, 7034178 (2015).

CrossRef - Margreat, L., Hari Krishnan, G. “Stastical approach for diagnosis of diseases using histopathology data”, International Journal of Pharma and Bio Sciences, 6(2), pp. B199-B203.

- Umashankar, G., Hari Krishnan, G., Abraham, S., (…), Kirubika, T.R., Rajendran, M. Proximity sensing system for retinal surgery patients, Journal of Chemical and Pharmaceutical Sciences, 8(4), pp. 607-610.

- Ilangovan, N., Hari Krishnan, G. “Wheel chair movement control using human input: Comparative study approach”, Research Journal of Pharmaceutical, Biological and Chemical Sciences, 6(3), pp.568-570 (2015).

- Radhakrishna Rao, G., Hari Krishnan, G. Comparative study of pacemaker energy harvesting techniques, Research Journal of Pharmaceutical, Biological and Chemical Sciences, 6(1), pp.1545-1547 (2015).

- Sabarivani, A., Hari Krishnan, G. “Home health assistive system for critical care patients”, Research Journal of Pharmaceutical, Biological and Chemical Sciences, 6(2), pp.629-633 (2015).

- Hari Krishnan, G., Hemalatha, R.J., Umashankar, G., Ahmed, N., Nayak, S.R., “ Development of Magnetic Control System for Electric Wheel Chair Using Tongue”, Advances in Intelligent Systems and Computing 308 AISC (VOLUME 1), pp.635-641 (2015).

CrossRef - Hemalatha, R.J., Krishnan, G.H., Umashankar, G., Abraham, S. “Computerized breast cancer detection system”, Biosciences Biotechnology Research Asia 11(2), pp.907-910 (2014).

CrossRef - Abraham, S., Krishnan, G.H., Hemalatha, R.J., Divakaran, S., Umashankar, G. “Design of voice based pill ejector system”, Biomedical and Pharmacology Journal, 7(1), pp.231-234 (2014).

CrossRef - Umashankar, G., Hari Krishnan, G., Hemalatha, R.J., Abraham, S., Divakaran, S. “ Assistive system for remote accident patients”, Research Journal of Pharmaceutical, Biological and Chemical Sciences, 5(5), pp.516-520 (2014).