Sudhaldev Mohapatra and C. B. Jha

Department of Rasa Shastra, Faculty of Ayurveda, Banaras Hindu University India.

Abstract

Ancient pharmaceutical techniques are rich enough for preparation of metallic/mineral bhasmas, a unique and important dosage form, administered internally in Ayurvedic practice. The quality control methods like varitara, rekhapurna, niruttha etc. described for different bhasmas in classical texts are very scientific and worthy even if in today’s era. Both physical and chemical assessments of bhasma in naked eye observation are really due to the excellent perception of ancient Acharyas for authentication of prepared bhasma. Swarna Makshika is an important raw material containing copper; iron & sulphur as major ingredient have been used to treat different diseases in its bhasma form since many centuries. In current research work Swarna makshika is processed with lemon juice and by using conventional puta system of heating to achieve its bhasma. The bhasma thus prepared is validated by using ancient quality control techniques.

Keywords

Bhasma; Swarna Makshika; Quality Control; Marana

Download this article as:| Copy the following to cite this article: Mohapatra S, Jha C. B. Ancient pharmaceutical techniques of Bhasma and its quality control with special reference to Swarna Makshika Bhasma. Biomed Pharmacol J 2010;3(1) |

| Copy the following to cite this URL: Mohapatra S, Jha C. B. Ancient pharmaceutical techniques of Bhasma and its quality control with special reference to Swarna Makshika Bhasma. Biomed Pharmacol J 2010;3(1). Available from: http://biomedpharmajournal.org/?p=2456 |

Introduction

Swrana Makshika [SM] is a mineral which is frequently used in its bhasma form to treat so many diseases like anemia, diabetic syndrome, insomnia and also in diseases caused by high lipid profile. There are lots of pharmaceutical processing techniques for Swarna makshika are described in literature of Rasa Shastra (Indian alchemy/ pharmaceutics). The bhasma of said material is prepared in two steps i.e. shodhana and marana. For both processes several techniques like roasting, heating & quenching etc. for shodhana and puta system of heating, kupipakwa mode of heating etc. for marana are available by using different auxiliary materials (i.e. other than [SM]). Lemon juice as ancillary material for both shodhana and marana, roasting technique for shodhana and puta system of heating for marana are frequently used for [SM]. Quality controls for bhasmas are well described in classical texts in very systematic manner, covering all aspects to assess the bhasma physic-chemically. The naked eye, favorable observations for bhasma Pariksha in Rasa Shastra is hallmark of its confirmation for clinical practice.

Pharmaceutical Processing’s of Swarna Makshika:

Shodhana of Swarna Makshika

Principle

Roasting with frequent addition of lemon juice

Materials and Method

Materials

Raw materials

Raw Swarna Makshika (Procured from the Ayurvedic Pharmacy, I.M.S, BHU)

Lemon juice (lemon is procured from the market and juice is extracted)

Equipments

Iron mortar& pestle, heating device; iron kadhai, ladle, pyrometer, weighing balance.

Method

At first Swarna Makshika was made into powder by iron mortar & pestle and taken in a clean and dry iron kadhai (pan), heated on the charcoal furnace at about a temperature of 8500c-9000c with frequent addition of lemon juice.

During the process an iron plate was covered over the iron kadhai to avoid the loss of material due to dusting. This process was carried out till cessation of sulphur fumes and appearance of red colour in the material.

The above procedure was carried out for three days.

Observations

During the heating of Swarna Makshika, fumes of sulphur odor was observed.

During the addition of lemon juice to the heating iron kadhai, containing Swarna Makshika dusting of the material was observed.

Initially the colour of Swarna Makshika was observed greenish black that gradually become purple and finally reddish brown colour was observed after completion of the process.

Total duration of 3days was required for completion of shodhana After completion of the process loss in weight of raw material was observed.

Marana of Swarna Makshika

Principle

Puta system of heating with 04 kg. Cow dung cake.

Materials and Methods

Materials

Raw materials

Suddha Swarna Makshika (prepared in the above stated process).

Lemon juice q.s. (lemon is procured from the market and juice is extracted)

Equipments

Stone mortar with pestle, spatula, earthen casseroles (sarava), rag & mud (kapad miti), cow dung cake, puta system of heating, pyrometer.

Method

The whole process of marana is completed in following sub steps, those have very significant role towards the quality of finished product.

Bhavana (Wet Trituration)

Accurately weighed suddha swarna makshika powder was taken into a clean and dry stone mortar. Then freshly prepared lemon juice was poured into the mortar (khalva), till it causes complete dipping of all the material in the mortar (khalva).

Continuous trituration was done by adding lemon juice when required, till the paste formed become sufficiently smooth and features of proper bhavana were observed. The same procedure was executed for each firing till the desired quality of bhasma is achieved.

Pelletisation

After completion of the bhavana process the paste thus formed is subjected to pelletisation. In this step pellets of uniform size and thickness were prepared and dried in sun shine.

Sarava Samputikarana

Properly dried, weighed, pellets were arranged inside the sarsva so as to facilitate proper distribution of heat to all the pellets.

Then another sarava was covered over it so as to fit perfectly by mouth to mouth, then the joint was sealed by turning the kapad miti for seven times and dried in sun shine.

Puta system of heating

Properly sealed and dried samputa was subjected to puta system of heating with four kg cow dung cake in each time.

During heating in puta system the dried samputa containing pellets was kept in between the cow dung cakes and cow dung cakes were arranged properly so that the uniform heat could be provided to the samputa from all corner.

Pyrometer was set at the base of the samputa to record the temperature pattern during the process.

Observations

The white fume with sulphur odor was observed during the early firings.

Gradually flame was appeared and reached around 1ft high, then slowly declined.

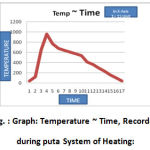

Temperature pattern was recorded through the pyrometer; on every15 min. 9800C was observed the highest peak temperature and was retained for about 05 min.

Initial greenish-black pellets were turned to brownish-black after 3rd puta, from 3rd to 8th puta colour of product was observed blackish-brown and testing parameters did not sustain.

After 11th firing the colour of the product was observed Reddish brown and found competent with all the bhasma parikshya including amla parikshya.

After completion of the process finally weight gain was observed.

|

Figure 1 |

Table 1: Showing Temperature pattern Observed in Puta System of Heating, for 4 kg. Cow dung cake.

| Sl. No. | Time (min) | Temperature (0C) |

| 1. | 0 | 40 |

| 2. | 15 | 120 |

| 3. | 30 | 650 |

| 4. | 45 | 980 |

| 5. | 60 | 770 |

| 6. | 75 | 680 |

| 7. | 90 | 640 |

| 8. | 105 | 605 |

| 9. | 120 | 576 |

| 10. | 135 | 535 |

| 11. | 150 | 410 |

| 12. | 165 | 365 |

| 13. | 180 | 295 |

| 14. | 195 | 230 |

| 15. | 210 | 160 |

| 16. | 225 | 100 |

| 17. | 240 | 40 |

|

Figure 2: Graph: Temperature ~ Time, Recorded during puta System of Heating |

Ancient quality control parameters followed for evaluation of Bhasma

Rekhapurnatvam: A pinch of bhasma was taken in between the thumb and index and rubbed. It was observed that the bhasma enters into the lines of the finger which was not easily cleansed out from the cleavage of finger lines. It signifies the smaller particle size of bhasma even if in the nano-range.

Varitaratavam: Small amount of the prepared bhasma was taken and sprinkled over the silent water taken into a beaker. It was found that the bhasma particles float over the surface of the water. It indicates the lightness of bhasma.

Uttama: The prepared bhasma was found to with stand on floating on water surface when one rice particle was placed over it. It confirms the very lightness of bhasma

Nisvadutvam: The prepared bhasma was found tasteless when a small amount was kept over the tongue. This test signifies the tastelessness of bhasma and facilitates its palatability for all.

Dantagre na kach kacha iti: When a small amount of the bhasma was placed between the teeth, no any sandy feeling was appreciated. This test proves the smoothness of the bhasma

Nischandratvam: The prepared bhasma must have loss of shinning and metallic luster even on observing through magnifying glass. This indicates absence of free metal.

Amla Parikshya: A pinch of prepared bhasma was mixed with little amount dadhi (curd) taken in a clean and dry Petridis, kept for 24h. and then observed for any colour change. No colour change of dadhi (curd) was observed. The same procedure was followed with lemon juice taken in a test tube and same observation was found. This test confirms absence of free metal.

Avami: Intake of small amount of the bhasma prepared did not produce any nausea / vomiting.

Specific Taste with Lemon juice and curd

As one of the composition of raw material is copper, the prepared bhasma was subjected to lemon juice and curd taste. It was found that after mixing prepared bhasma with both lemon juice and curd intimately there was no colour change observed both in short term as well as long term reaction indicates bhasma prepared properly.

Discussion

Literatures of Rasa Shastra are enriched with pharmaceutical processing techniques of metals and minerals. Amongst different processing techniques like roasting, heating and quenching, pounding etc. roasting with lemon juice is found suitable for swarna makshika shodhana. For marana 04 kg. cow dung cake as fuel is found suitable for preparation of its bhasma in a total of 11 number of firings (putas). The quality controls of metallic bhasmas are well defined in ancient texts and cover all the aspects of its internal administration so far as safety and efficacy is concerned. The assessments are based on naked eye observation but these are very minute and close surveillance to confirm the quality of bhasma. Sustaining with all the prescribed physical assessment like varitara, rekhapurna etc. and chemical assessment like amlapariksha substantiate the makshika bhasma for its clinical practice.

Conclusion

Roasting with frequent addition of lemon juice is found suitable for shodhana of swrana makshika

Puta system of heating with 04 kg cow dung cake in each firing and in total of 11 firing is essential for preparation of swarna makshika bhasma.

Ancient quality control parameters for metal/mineral bhasma are very systematic, easy and low cost with confirmation of its safety and efficacy which is time tasted and also proved by different researches[4] in current language.

The modern tools and techniques are essential for standardization and validation of bhasma in terms of current language.

References

- The Ayurvedic Formulary of India, chapter , 21:18, pp-247, of India, Ministry of health and family welfare department of Indian system of medicine and homoeopathy, Part-I, second edition, 2003, New Delhi. Sharma Sadanand, Rasa Taranginee, Chapter-21, Verse-21/7-11, Pp-521, Motilal Banarasi das Publication, Varanasi.

- The Ayurvedic Formulary of India, chapter , 21:18, pp-247, of India, Ministry of health and family welfare department of Indian system of medicine and homoeopathy, Part-I, second edition, 2003, New Delhi Sharma Sadanand, Rasa Taranginee, Chapter-21, Verse-21/19-20, Pp-523, Motilal Banarasi das Publication, Varanasi. Sudhaldev Mohapatra, et al, Standardization of Swarna Makshika Bhasma- A Pharmaceutical Study, Aryavaidyan, Vol. -XXI, No-01/Aug-Oct/2007, The Aryya Vaidyasala, Kottakkal

- Acharya Vagbhata, Rasa Ratna, Samucchhaya, edited by Sri Dattatreya Ananta Kulkarni, Chapter-8/26-30, 10/48-50, Meharchand Lachmandas, Publication, New Delhi, Reprint, 1998

- Mohapatra et al, Process Standardization of Makshika Bhasma and its experimental evaluation for hypnotic and behavioral activities on experimental animal, Dept. of Rasa Shastra, Banaras Hindu University, Varanasi. 2006 Sridurga Chinta et al comparative study of Makshika Bhasma & the bhasma prepared with the combination of tamra and loha, Dept. of Rasa Shastra, Banaras hindu University, Varanasi, 2005

- Chaudhary et al, comparative study of bhasma of Makshika & Makshika satva with special reference to its analytical, physico-chemical and hematological assessment, Dept. of Rasa Shastra, Banaras hindu University, Varanasi, 2001