Ramin Shahrad Bejestani1, Fahimeh Nemati2 and Saeid Akbarzadeh Kolahi3*

1Herbal Medicines Research Center, Pharmaceutical Sciences Branch, Islamic Azad University, Tehran, Iran (HMRC).

2Department Of Biotechnology, Faculty Of Advanced Sciences and Technology, Pharmaceutical Sciences Branch, Islamic Azad University, Tehran, Iran (IAUPS).

3Department Of Pharmacology and Toxicology, Faculty Of Pharmacy, Pharmaceutical Sciences Branch, Islamic Azad University, Tehran, Iran (IAUPS).

*Corresponding Author E-mail: Saeidakbarzadeh4@gmail.com

DOI : https://dx.doi.org/10.13005/bpj/983

Abstract

Clavulanic acid acts as an enzyme inhibitor like sulfactam and azobactam produced by Streptomyces Clavuligerus bacteria. This product plays a major role in pharmaceutical industry especially in producing Co-Amoxiclav. The fermentation stage plays a major role in producing secondary products. Nitrogen substrate is one of the main and most costly elements of the cultivation environment in this stage. Thus, utilizing affordable nitrogen resources with an acceptable level of output which is native and can be accesses with a constant quality is of great significance. The present research seeks to study the effect of various densities of rapeseed meal as the natural source of nitrogen and the cost in producing clavulanic acid. In this research, we utilized Streptomyces Clavuligerus strain to produce clavulanic acid. The main source of nitrogen which is soybean flour was replaced by rapeseed meal. Spore suspension was cultivated in seed ripening environment. Having formed Mycelium, it was then transferred to clavulanic production medium. The final product was cultivated for a period of 9 days in the temperature of 28 and the level of clavulanic produced was measured in certain days using spectrophotometer and HPLC. The samples collected from the cultivation medium were compared against one another in terms of the amount of clavulanic acid produced through spectrophotometer and HPLC. As it turned out, the highest amount of clavulanic acid was produced on the 8th day of cultivation in the medium containing 25 gr/L rapeseed meal as the source of nitrogen. This amount is equal to the amount produced in the main environment of clavulanic acid production which contained soybean flour as the source of nitrogen. Considering the amount of clavulanic acid produced in the medium containing rapeseed meal as the source of nitrogen and keeping in mind the favorable characters of rapeseed such as low price, availability, and the high rate of production, we may conclude that this product can be a good replica for the source of nitrogen in the absence of soybean flour.

Keywords

Clavulanic Acid; Rapeseed Meal; Nitrogen; Streptomyces Clavuligerus

Download this article as:| Copy the following to cite this article: Bejestani R. S, Nemati F, Kolahi S. A. Production of Clavulanic Acid by Streptomyces Clavuligerus Bacteria using Rapeseed Meal as The Source of Nitrogen. Biomed Pharmacol J 2016;9(2). |

| Copy the following to cite this URL: Bejestani R. S, Nemati F, Kolahi S. A. Production of Clavulanic Acid by Streptomyces Clavuligerus Bacteria using Rapeseed Meal as The Source of Nitrogen. Biomed Pharmacol J 2016;9(2). Available from: http://biomedpharmajournal.org/?p=7811 |

Introduction

The diseases caused by micro-organisms are considered to be serious threats against people’s health all around the world and a lot of money is spent to treat them. Thus, it is of great importance to find new antibiotics and enhance the effectiveness of the current ones. We may also say that antibiotics are of great economical importance (1). One of the current problems with using these antibiotics is the resistance of microbes against them. Betalactamase which is a bacterial enzyme that results in the hydrolysis of betalactam loop in the antibiotics is one of the resistance patterns observed. In order to counter the resistance shown by betalactamase, we can protect sensitive betalactams with the aid of a Betalactamase inhibitor (2). Clavulanic acid is a betalactamase inhibitor whose clinical application began in 1981 (3). This inhibitor is the natural product of Streptomyces Clavuligerus fermentation which results in the inhibition of intracellular and extracellular betalactamases in group A and Cloxacillin decomposing enzyme in group D (3 & 4). This inhibitor results in the competitive and non-retractable inhibition of betalactamases (4). Considering the application of clavulanic acid in pharmaceutical industry, the cheap production of this material can be a great aid to our economy and pharmaceutics industry as each kilogram of this material costs about 450$ (5). 30 to 40 percent of production cost is spent on the appropriate cultivation medium, thus selecting an appropriate medium which results in maximum output for each gram of substrate and results in the higher rate of production and is cheaper and more easily affordable is of great significance (6). Carbon and nitrogen resources are two example of the resources used in cultivation medium. Optimization of the composition of the medium plays a major role in increasing the production rate of biological products, and nitrogen resources play a major role here (7). As the main source of nitrogen, rapeseed meal has properties such as abundant production and availability. It has the appropriate chemical compounds and is cheap rendering its utilization in the industry of metabolite production quite affordable. This research attempted to study the effect of utilizing rapeseed meal as the source of nitrogen in the fermentation medium of the bacteria generating clavulanic acid (8).

Material and Method

Streptomyces Clavuligerus strain was fetched from Iranian Industrial Bacteria and Fungus Collection center. To achieve the maximum production of spore, an exclusive medium (10 gr/L Malt extract, 4 gr/L yeast extract, 4 gr/L glucose, 2 gr/L calcium carbonate and 12 gr/L agar) was prepared and poured declivitously inside the funnel. This bacteria was cultivated on an exclusive medium for 14 days in a temperature of 28 . To prepare the spore suspension, about 10 milliliters of sterilized Tween 80 with a density of 0.1% was added to the funnel containing spore. The surface of the medium was scratched slowly until the spores got separated. In the next step and in order to force the spores to commence Mycelium growth and prepare inoculants liquid, to milliliters of the spore suspension was added to the flasks containing Mycelium exclusive growth medium (10 gr/L bacto peptone, 20 gr/L glycerol, 10 gr/L malt with a PH level of 7). The medium was shaken in e temperature of 28 for 48 hours with a pace of 200 rpm.

Investigating and selecting the best medium containing Mycelium as the inoculants liquid

To select the best flask for seeding, 5 milliliter sample was collected from every flask and the samples were studied in terms of the growth morphology of bacteria, absence of microbial pollution, and the biomass formed. After preparing bacterial development on the slides, warm coloring was conducted in accordance with standard protocol and its pollution and morphology were checked. To calculate the biomass formed, the following formula was used

B – A = 1 milliliter of the seeding medium weight

C – A = sediment weight

A represents the pure weight of microtube, B represents the weight of microtube containing 1 milliliter of the sample, and C represents the dry weight of mycelium after sedimentation.

Producing clavulanic

To produce clavulanic by Streptomyces Clavuligerus bacteria, the exclusive medium to produce clavulanic with a density of 20, 25 and 30 gr/L of rapeseed meal was used as the source of nitrogen. The composition of the medium is represented in the table below (table 1). The witness medium contained soybean flour as the source of carbon.

Table 1: The medium used to produce clavulanic acid

| Material used | Amount (gr/L) |

| starch | 10 |

| rapeseed meal | 20 – 25 – 30 |

| corn oil | 23 |

| Ca3 (po2)4 | 1.2 |

| Znso4 H2o | 0.001 |

| Feso4 7H2o | 0.001 |

| Mncl2 4H2o | 0.001 |

The exclusive cultivation medium was prepared in flasks with a capacity of 500 milliliter and 5 to 10 percent of the volume of the medium was filled with the inoculant. The flasks were then cultivated in incubator’s shaker in a temperature of 28 with a pace of 200 rpm for 9 days. Some 5 milliliter sample was collected everyday from the 3rd to the 9th day. The samples were studied for their PH and formation of biomass. The samples were then centrifuged with a pace of 4000 rpm for 20 minutes and the upper solution was transferred to another vial. To exclude the intervening proteins using phosphoric acid, PH of the fermentation liquid was set to 3 and the resulting solution was centrifuged for 20 minutes with a pace of 4000 rpm. The upper fluid was used to measure clavulanic acid produced.

Clavulanic acid measurement

Spectrophotometer and liquid chromatography were used to measure the amount of clavulanic acid produced.

To measure the amount of clavulanic acid produced through spectrophotometer, first the standard curve was drawn using clavulanic potassium provided by Dana pharmaceutical company. For this purpose, 50 milligram of the standard clavulanic potassium was increased to the value of 100 ml using 0.1 molar phosphate buffer and read in optical absorption 278 nm wavelength. The same method was utilized to study the optical absorption of the clavulanic produced.

To measure clavulanic acid through HPLC technique, the standard protocol of this method was utilized (9, 10, 11).

Results

Prior to the fermentation phase and in order to choose the inoculant, we need to make a correct assessment of the best seeding flask. Thus, the biomass, pollution and morphology of the cultivation mediums were studied.

|

Figure 1: The appropriate growth of myceliums without any pollutions

|

As it is seen in figure 1, myceliums had an appropriate growth during a 48-hour period of cultivation and there is no pollution in them. On the other hand, the biomass produced for inoculation during a 48-hour cultivation period ranged from 10 to 15 percent which is considered to be an appropriate condition for inoculation.

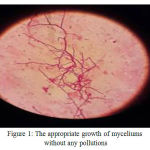

The cultivation of the bacteria in clavulanic production medium was studied. It is clear that the biomass increases on a daily basis up to the 8th day, but the reduction of biomass and death occur on the following days (chart 1).

|

Chart 1: Biomass fluctuations

|

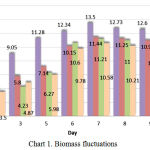

Studying the PH of various production mediums was indicative of this fact that the levels of PH had dropped on the initial days of production and had increased from the 8th day onward (chart 2).

|

Chart 2: Fluctuations of the acidity of the production medium in various densities of rapeseed. 20 (less), 25 (equal) and 30 (more) gr/L

|

Chart 2. Fluctuations of the acidity of the production medium in various densities of rapeseed. 20 (less), 25 (equal) and 30 (more) gr/L. The influence of rapeseed meal on the production rate of clavulanic acid was studied using spectrophotometer and HPLC. Chart 3 represents the spectrophotometer of the 8th day of fermentation with all the three densities (20, 25, 30 gr/L) of rapeseed meal (chart 3).

|

Chart 3: Spectrophotometer of the 8th day of fermentation with three densities of 20, 25 and 30 gr/L

|

As it is seen in chart, higher densities of rapeseed meal resulted in a higher rate of production. On the other hand, the production rate of clavulanic acid with various densities of rapeseed in different days was analyzed using spectrophotometer (chart 4).

|

Chart 4: The spectrophotometer results of clavulanic acid levels in different days and with various densities of rapeseed of 20 (less), 25 (equal) and 30 (more) gr/L

|

The production rate of clavulanic acid in various days with a rapeseed meal density of 25 gr/L as the source of nitrogen was measured using HPLC method. The results are presented in chart 4 (chart 5).

|

Chart 5: the production rate of clavulanic acid in different days with a rapeseed meal density of 25 gr/L as the source of nitrogen through HPLC. The word Protocol in the image refers to the main cultivation medium which contains soybean flour

|

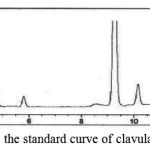

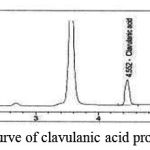

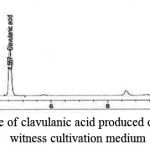

According to chart 5, the highest rate of production has been recorded on the 8th day. The standard curve was drawn for clavulanic acid (chart 6). The production rates in both the production and witness mediums on the eighth were compared against one another using HPLC technique (charts 7 & 8).

|

Chart 6: the standard curve of clavulanic acid

|

|

Chart 7: HPLC curve of clavulanic acid produced over 8 days

|

|

Chart 8: HPLC curve of clavulanic acid produced over 8 days using the witness cultivation medium

|

Discussion

Higher rate of production is a major goal in biological researches. As the antibiotics rank second among these products in terms of their application, various researches have been conducted in order to investigate increase the production rate of these products with microorganism’s strain or cultivation medium conditions optimization being the main focus of the research. One of the important notes in optimization of the medium’s condition is selection of a good medium for cultivation and development of microorganisms so that they can demonstrate their potential and capability in producing products (12). To achieve the maximum product production, full analysis of microorganism cultivation conditions, influence of various elements of substrate, cultivation medium composition and the amount of each element, and the physical and chemical factors of the environment are the important notes that need to be taken into consideration. In this research, we studied application of rapeseed meal in production of clavulanic acid with the goal of optimizing fermentation medium composition in terms of nitrogen resources (13). Hamdi et al (2004) studied utilization of some other oils as replicas for the carbon source of glycerol and their results showed that olive oil increased the production rate of clavulanic acid twice as much as corn oil, flax oil and glycerol (14). In a study conducted by Lee et al (1996), Arginine and Threonine were added to glycerol fermentation cultivation medium and the production rate was reported to have increased 18% (15). On the other hand, Monir et al (2010) investigated the influence of metal ions on the production rate of clavulanic acid. In this research, Ca+2, Cu+2, Fe+2, Mg+2, Mn+2, and Zn+2 were studied as the metal ions and it turned out that chloride salts have a negative effect on the production rate of clavulanic acid (16). In a research conducted by Anthony et al (2013) where soybean protein and rapeseed meal were studied in terms of their carbon and nitrogen resources, a direct relationship was observed between the production rate of clavulanic acid and reduction/rise of oil density. The highest amount of clavulanic acid produced was 906 mg/mL achieved by using 40 g/L soybean flour and an oil density of 16 gr/L. It turned out that increasing soybean flour as the source of nitrogen results in the higher rate of product production (17).

According to the studies conducted in this field, there is a direct link between the shape and the development of hyphaes and their production rate. Hyphaes have long arms and many branches and they will sustain this condition as far as there are sufficient compounds in the cultivation environment. As it has been reported that several tones of clavulanic acid are produced and consumed every year, this large amount of the material requires a lot of fermentation cultivation medium and nitrogen resources. According to the results of the research, our experiments have reduced both the product and the price. A not-very-complicated calculation reveals that using rapeseed meal does not result in that much optimization of products and reduction of the prices is not sensitive enough so that we may consider rapeseed a good replica for soybean. However, under certain conditions such as shortage of soybean flour in the country or the disproportionate rise of its price compared to rapeseed, rapeseed meal can be a good alternative to soybean flour. Considering other researches conducted on this issue and the current production rate of it in Iran is indicative of the fact that using rapeseed meal to produce fermentation products such as antibiotics and other secondary metabolites is a useful and affordable endeavor.

Conclusion

Considering the price and frequency of rapeseed meal (compared to soybean flour), availability and the relatively equal product production in the media containing rapeseed meal and soybean flour as sources of nitrogen, we arrive at the conclusion that rapeseed meal can be a good alternative for nitrogen source in the absence of soybean flour.

References

- Bader,F.G.(1986). Physiology and Fermentation Development In : The Bacteria : A treatise on structure and function . IX , Antibiotic producing

- Demain, Arnold L, ( 2000) , Small bugs , big business: The economic power of microb ,Biotechnology Advances 18 , 499-.415

- The Physiology of Clavulanic Acid Production by Streptomyces Clavuligerus Publisher University of Surrey,2000

- Elander, R.P (2003) , Industrial of BetaLactam Antibiotic , Appl. Microbial Biotechnol :583-293

- Heydarian , Mohammad et all , ( 1996) , The Effect of culture Condition on the production of Erythromycin by Saccharopolyspora erythraea in Batch Culture , Biotchnologe letters , Vol 13 , No 10 , 1181-.6811

- Lancini , G; Lorenzetti , R,( 1993) production of secondary metabolites, biotechnology of antibiotics and other bioactive microbial metabolites512,-.522

- Clerck , C.J.,Landy , D. and Buschell, M.E,( 1995) Oxygen limitation can induce microbial secondary metabolite formation :investigation with miniature electrodes in shaker and bioreactore culture microbial366 : 141 .-.966

- Uçkun Kiran E .Salakkam A. Enhancing the value of nitrogen from rapeseed meal for microbial oil production. Enzyme Microb Technol. 2012 May 10;50(6-7):337-42. doi: 10.1016/j.enzmictec.2012.03.004. Epub 2012 Mar 22.

- WHO monograph on good agricultural and collection practices (GACP) for Artemisia annua L. 2006.

- Artemisinin Monograph, in The International Pharmocopeia. 2003, WHO: Geneva. p. 185-233.

- Widmer, V., D. Handloser, and E. Reich, Quantitative HPTLC analysis of artemisinin in dried Artemisia annua L.: a practical approach. J. Liq. Chrom. Related Technologies, 2007. 30: p. 2209-2219

- Heydarian , Mohammad et all ,( 1998) , The Influence of Agitation on Morphology , Rheology and Erythromycin production in Saccharopolyspora erythraea Culture , univ. of London, Dept of biochemical Engineering .

- Lancini , G; Lorenzetti , R,( 1993) production of secondary metabolites, biotechnology of antibiotics and other bioactive microbial metabolites512,-.522

- Hamedy , J, ( 2004) , Effect of shark oil on the growth of Saccharopolyspora erythraea and Erythromycin production.

- Lee,C.J.(1996),Managing Biotech . In drug development , CRC press PP.1-.6

- Mounir M. Salem-Bekhit1, Fars K. Alanazi1 and Ibrahim A. Alsarra ,2010, Improvement and enhancement of clavulanic acid production in Streptomyces clavuligerus using vegetable oils, African Journal of Biotechnology Vol. 9(40).

- Antonio .Bellão . 2013. Production of clavulanic acid and cephamycin C by Streptomyces clavuligerus under different fed-batch conditions. Braz. J. Chem. Eng. vol.30 no.2 São Paulo Apr./June 2013. http://dx.doi.org/10.1590/S0104-66322013000200004.