Sukumaran. V.G1 , Mensudar. R2*

1Professor, Department of Conservative Dentistry, Sree Balaji Dental College and Hospitals, Bharath University, Pallikarani, Velachery, Chennai – 600100 2Professor and Head of the Department, Department of Conservative Dentistry, Sree Balaji Dental College and Hospitals, Bharath University, Pallikarani, Velachery, Chennai – 600100

DOI : https://dx.doi.org/10.13005/bpj/720

Abstract

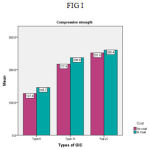

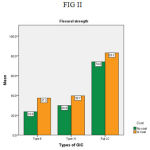

Glass Ionomer Cement has been widely used since their introduction by Wilson and Kent (1971) in a wide variety of clinical applications in dentistry. Since water plays a key role for proper maturation of GIC, its physical properties can be compromised by both water contamination and dehydration during the initial setting stages. To prevent these, water exclusion is recommended during this vulnerable setting stage. So, the aim of this study was to investigate the effect of G-Coat plus (nanofilled self-adhesive light cured resin) on both conventional and RMGIC by evaluating the mechanical properties (compressive strength (CS), flexural strength (FS), surface hardness (SH)) on three different types of GIC (Type II, Type XI, and Fuji LC). Two conventional GIC (Type II and Type IX) and one RMGIC were used in this study (Group I – III) respectively. The three groups were subdivided into Subgroup A and B. Each group contained 30 samples, thus a total of 216 samples were prepared. Among the 72 samples in each group, 12 samples were used to evaluate CS, 12 samples for FS, and the remaining 12 samples were used for surface hardness. The samples were then tested to investigate the effect of surface coating by evaluating their mechanical properties. The values obtained were tabulated and analysed by Independent sample t-test and ANOVA followed by Post-hoc; Tukey’s B test (Table I to III). Comparison of subgroups in Type II, Type XI and Fuji LC indicate that the mean values of the two groups, namely No coat and G coat, are different in all three types of GIC ( FIG I and FIG II) in their mechanical property. Comparing among the groups, the samples coated with G-coat plus showed a higher value for all types of cements. Within the limitation of this study, it has been shown that the samples that where protected with light cured self adhesive coating (G-coat plus) exhibited an increased mechanical strength when compared to the unprotected samples. Further long-term study is needed to check the longevity of the material in simulated oral environment.

Keywords

G-coat plus; glass ionomer cement; flexural strength; surface hardness; compressive strength

Download this article as:| Copy the following to cite this article: Sukumaran V. G, Mensudar R. To Evaluate the Effect of Surface Coating on Three Different Types Glass Ionomer Restorations. Biomed Pharmacol J 2015;8(October Spl Edition) |

| Copy the following to cite this URL: Sukumaran V. G, Mensudar R. To Evaluate the Effect of Surface Coating on Three Different Types Glass Ionomer Restorations. Biomed Pharmacol J 2015;8(October Spl Edition). Available from: http://biomedpharmajournal.org/?p=3680> |

Introduction

Glass Ionomer Cement has been widely used since their introduction by Wilson and Kent (1971) in a wide variety of clinical applications in dentistry. It is one of the restorative material that consist of fluroaluminosilicate glass powder and an aqueous polyacid, which sets by acid-base reaction. Their unique properties are anticariogenic potential due to fluoride release and recharging, biocompatibility with low toxicity and physiochemical bonding to both enamel and dentin. However, the limitations of conventional GIC is due to its inferior mechanical properties such as low wear resistance and brittleness, low strength, rough surface texture and opaqueness, susceptibility to moisture, which limits their use.[1] One of the major drawback is low fracture strength and increased occlusal wear rate when compared with other restorative materials. Thus special attention is needed to be looked into the mechanical properties of the GIC. Over the period, they have undergone constant improvement in order to fulfil the current market trends and also to satisfy the function and aesthetic representation. They are also inexpensive when compared to resin composite restorations. Thus, mechanical properties of GIC have been investigated since their development and concerns have remained even after the development of resin modified GIC (RMGIC).[2] Eventually considerable efforts are made for strength enhancement, which are still being researched in several aspects.

Since water plays a key role for proper maturation of GIC, its physical properties can be compromised by both water contamination and dehydration during the initial setting stages.[3] Early moisture contamination drops the mechanical strength of GIC restorations and makes its surface more prone to erosion and abrasion. To prevent these, water exclusion is recommended during this vulnerable setting stage. This is achieved by surface coating agents that were recommended in the past, which include petroleum jelly, cocoa butter, waterproof varnishes and even nail varnishes. But, with time, these coatings are lost by oral masticatory wear. Among the various surface coating strategies, light-polymerized resin coatings have been considered as the optimal surface protecting agent.[4] Hotta et al. found, that the use of light-polymerizing bonding or glazing agents was able to limit water movement across the setting cement surface.

So, the aim of this study was to investigate the effect of G-Coat plus (nanofilled self-adhesive light cured resin) on both conventional and RMGIC by evaluating the mechanical properties (compressive strength (CS), flexural strength (FS), surface hardness (SH)) on three different types of GIC (Type II, Type XI, and Fuji LC).

Materials and Methods

Two conventional GIC (Type II and Type IX) and one RMGIC were used in this study (Group I – III) respectively. The three groups were subdivided into Subgroup A and B. Each subgroup contained 36 samples, thus a total of 216 (36 x 6) samples were prepared. Among the 36 samples in each subgroup, 12 samples were used to evaluate CS, 12 samples for FS, and the remaining 12 samples were used for surface hardness. All the material was manipulated according to the manufactures’ instructions. For the light cure GIC, all the procedures were similar except that the samples were exposed to light source (LEDition, Ivoclar vivadent) for about 20 seconds. All the samples under subgroups B was coated with a protective nanofilled adhesive resin (G-Coat plus) and was then light cured for 20 seconds. The subgroup A samples did not receive any surface coating. All the samples were allowed to set at room temperature for 1 hour and were then stored in distilled water at 37 C for 24 hours. The samples were then tested to investigate the effect of surface coating by evaluating their mechanical properties.

Compressive tests were performed at a cross head speed of 1 mm/min with universal testing machine (Lylod instrument, LR100K) using 6 mm x 3 mm diameter circular specimen. A three-point bending test (Instron 3382, UK) was used to determine the flexural strength (25 mm x 2 mm x 2 mm) at a cross head speed of 0.1 mm/min. Surface hardness of the samples were performed using a diamond indenter (Micro-Duromat, 400E, Austria) with 100 g load on 6mm x 3 mm dimensions sample. Before testing, the accurate dimensions of each sample were checked.

Results

The values obtained were tabulated and analysed by Independent sample t-test and ANOVA followed by Post-hoc; Tukey’s B test (Table I to III). Comparisons of No coat and G coat in Type II, Type XI and Fuji LC indicate that the mean values of the two groups, namely No coat and G coat, are different in all the three GIC types in their mechanical property ( FIG I and FIG II) in their mechanical property. When G coat is applied, surface harnesses are found to be the same in GIC types Type II and in Fuji LC and it is found to be significantly higher in Type XI. Comparing among the groups, the samples coated with G-coat plus showed a higher value for all types of cements. Statistically significant difference were observed between the groups that were coated with G-coat plus and uncoated samples.

Table I: Surface Hardness

| Types of GIC | One way ANOVA | |||||||

| Type II | Type XI | Fuji LC | ||||||

| Mean | SD | Mean | SD | Mean | SD | F-Value | Sig. | |

| No coat | 24.24 | 1.13 | 33.68 | 1.15 | 22.61 | .98 | 362.436 | 0.000 |

| G Coat | 33.76 | 1.26 | 40.73 | .96 | 34.23 | 2.23 | 72.754 | 0.000 |

| Independent Samples t-test | Value: -19.445

Sig: 0.000 |

Value: -16.338

Sig.: 0.000 |

Value: -16.495

Sig.: 0.000 |

|||||

Table II: Flexural Strength

| Types of GIC | One-way

ANOVA |

|||||||

| Type II | Type XI | Fuji LC | ||||||

| Mean | SD | Mean | SD | Mean | SD | F-Value | Sig. | |

| No coat | 23.57 | 1.73 | 29.78 | 1.21 | 73.99 | 1.15 | 4713.573 | 0.000 |

| G Coat | 37.34 | 1.42 | 39.66 | .99 | 83.08 | 1.56 | 4382.964 | 0.000 |

| Independent Samples t-test | Value: -21.291

Sig.: 0.000 |

Value: -21.921

Sig.: 0.000 |

Value: -16.221

Sig.: 0.000 |

|||||

Table III: Compressive Strength

| Types of GIC | One way

ANOVA |

|||||||

| Type II | Type XI | Fuji LC | ||||||

| Mean | SD | Mean | SD | Mean | SD | F | Sig. | |

| No coat | 127.39 | 2.05 | 217.38 | 3.09 | 251.57 | 2.33 | 7725.758 | 0.000 |

| G Coat | 145.74 | 2.63 | 236.91 | 1.88 | 260.43 | .86 | 11815.660 | 0.000 |

| Independent Samples t-test | Value: -19.064

Sig.: 0.000 |

Value: -18.702

Sig.: 0.000 |

Value: -12.368

Sig.: 0.000 |

|||||

|

Figure I: Graphical representation of compressive strength |

|

Figure II: Graphical representation of flexural strength |

Discussions

GIC is water-based cement with water playing a critical role in the setting reaction. During the initial stage of setting reaction, the silica hydrogel (liquid state) of the cement has to be protected from additional water contamination to prevent cement dissolution. Once the cement has set (solid state), loss of water i.e cement dehydration has to be prevented to avoid cracking / crazing of the cement surface. Thus as the cement ages, the proportion of loosely-bound water decreases relative to the proportion of tightly-bound water.[5] Gemalmaz et al stated that early moisture contamination decreases the mechanical strength and makes the surface more prone to erosion and abrasion.

In this study, the effect of G-coat plus, a light cured protective coat, which contained uniformly dispersed nanofillers, was evaluated. Compressive strength is often used as a measure to evaluate the ability of the material to with stand the masticatory forces and the 3-point bending test is considered as a representation of the clinical situation of the forces exerted by the opposing cusp.[6,7] The result in Table II & Table III showed that RMGIC had higher FS and CS when compared to conventional GIC. This can be attributed to the dual curing nature of the cement. The plastic deformation behaviour of RMGIC is probably a major contribution to the higher FS and CS in addition to the dual crosslink. It can also be due to the integrated interface that is present between the glass particles and polymer matrix that present higher mechanical strength.[8,9]

In this study, the samples that were coated with G-coat plus presented higher values when compared to the unprotected samples. The single phase dispersed nanofillers (30 nm) that is present in G-coat plus has developed a ‘micro-lamination effect’ with uniform flow and complete wetting of the cement surface. This in turn, has developed a thick protective coating of about 35-40µm approximately.[10] This final lamination enables to form a smooth and glossy surface, which strengthens, protects and enhances the hardness of all GIC restorations. It protects the cement surface against excessive water contamination during the initial cure. Moreover the coating provides a dispersion hardened surface. It bonds well both to the tooth and cement surface and fills the voids, thus the mechanical stress gets dispersed by the toughened laminated layer.

The microhardness can be defined as the resistance of the material to indentation and penetration. Variability was observed with surface hardness, which showed a lower value in group III, subgroup B could be due to low filler content and flexible polymer matrix. The higher value of Group II, subgroup B could be due to very dense surface texture with tightly packed glass particles in the matrix resulted in a higher KHN.[11] Moreover, the infiltration of G-coat plus gives internal protection against cracks and voids by increasing the toughness. The dispersion of nanofillers reinforces the outer layer, which increases the wear resistance and protection against acid erosion.[12,13]

Thus the G-coat plus which is a self-adhesive, nano-filled resin coating provides a high hydrophilicity combined with an extremely low viscosity, which accounts for a perfect seal of GIC surface. The compounded nanofillers are thereby intended to protect the system against abrasive wear.

Conclusion

Within the limitation of this study, it has been shown that the samples that where protected with light cured self adhesive coating (G-coat plus) exhibited an increased mechanical strength when compared to the unprotected samples. Further long-term study is needed to check the longevity of the material in simulated oral environment.

Bibliography

- Prosser HJ, Powis DR, Brant P, Wilson AD. Characterization of glass-ionomer cements. 7. The physical properties of current materials. J Dent. 1984;12:231-40.

- Xie D, Brantley WA, Culbertson BM, Wang G. Mechanical properties and microstructures of glass-ionomer cements Dent Mater. 2000;16:129-38.

- Oilo G. Characterization of glass ionomer filling materials. Dent Mater. 1988;4:129-33

- Tiwari S, Nandlal B. Effect of nano-filled surface coating agent on fluoride release from conventional glass ionomer cement: an in vitro trial. J Indian Soc Pedod Prev Dent. 2013;31:91

- Cattani-Lorente MA, Godin C, Meyer JM. Mechanical behaviour of glass ionomer cements affected by long-term storage in water. Dent Mater.1994;10:37-44.

- Anstice HM, Nicholson JW, McCabe JF. The effect of using layered specimens for determination of the compressive strength of glass-ionomer cements. J Dent Res. 1992; 71:1871-4.

- Ramashanker, Singh RD, Chand P, Jurel SK, Tripathi S. Evaluation of adhesive andcompressive strength of glass ionomer cements. J Indian Prosthodont Soc. 2011;11:210-4.

- Zhang L, Tang T, Zhang ZL, Liang B, Wang XM, Fu BP. Improvement of enamelbond strengths for conventional and resin-modified glass ionomers: acid-etching vs. conditioning. J Zhejiang Univ Sci B. 2013;14:1013-24.

- Prosser HJ, Powis DR, Wilson AD. Glass-ionomer cements of improved flexural strength. J Dent Res. 1986;65:146-8.

- Bagheri R, Taha N, Azar M, Burrow M. Effect ofG-Coat Plus on the mechanical properties of glass-ionomer cements. Aust Dent J. 2013;58:448-53.

- Fatima N, Ali Abidi SY, Qazi FU, Jat SA. Effectiveness of commonly available surface protecting agents in maintaining microhardness of twocements. J Coll Physicians Surg Pak. 2013;23:315-8.

- Bonifacio CC, Werner A, Kleverlaan CJ. Coating glass-ionomer cements with a nanofilled resin. Acta Odontol Scand. 2012;70:471-7.

- Lohbauer U, Krämer N, SiedschlagG, Schubert EW, Lauerer B, Müller FA, Petschelt A, Ebert J. Strength and wear resistance of a dental glass-ionomer cement with a novel nanofilled resin coating. Am J Dent. 2011;24:124-8.