Andrey Ivanovich Shveyov1, Ivan Andreevich Shveyov1, Tatyana Vladimirovna Shveyova1, Ekaterina Ivanovna Shveyova1, Engel Rafikovich Galimov2, Elmira Engelevna Sharafutdinova2, Alexey Vitalievich Belyaev2

1Naberezhnye Chelny Institute, Kazan Federal University, Naberezhnye Chelny, 423800, Russia 2Kazan national research technical university named after A.N. Tupolev, Russia. Corresponding Author E-mail: Shveev_Andrey222@mail.ru

DOI : https://dx.doi.org/10.13005/bpj/579

Abstract

The paper analyzes the current state of technology of powder steels and potential use in its objectives methodology of multifractal parameterization. The objects of study were samples microstructure of carbon steels. Tasks in the study necessitated the use of standard methods for determining the mechanical properties of the metal, the method of multifractal parameterization, metallographic examinations and standard methods of statistical processing of the results. The influence of the conditions for obtaining images of the microstructure (magnification, the type of etchant, plane grinding) on multifractal parameters uniformity and order was studied. The conditions for image acquisition, excluding distortions of multifractal parameters were found. It was found that the use of multifractal parameterization provides increased strength characteristics of up to 8-10% and significantly (up to 40%) to reduce the cost of optimization by reducing the number of experimental studies.

Keywords

Structural state; powdered steel; forecasting; multifractal parameterization

Download this article as:| Copy the following to cite this article: Shveyov A. I, Shveyov I. A, Shveyova T. V, Shveyova E. I, Galimov E. R, Sharafutdinova E. E. S, Belyaev A. V. Prediction of the structural state of powder steels by multifractal parameterization. Biomed. Pharmacol. J.;8(1) |

| Copy the following to cite this URL: Shveyov A. I, Shveyov I. A, Shveyova T. V, Shveyova E. I, Galimov E. R, Sharafutdinova E. E. S, Belyaev A. V. Prediction of the structural state of powder steels by multifractal parameterization. Biomed Pharmacol J 2015;8(1). Available from: http://biomedpharmajournal.org/?p=537 |

Introduction

Recently there has been rapid development of technologies for the production of engineering products from powder materials. For example, of the powder steels are manufactured sealing, anti-friction, friction and other engineering products, whose properties are determined by the composition of powder steels, their structure and technology of obtaining.

A characteristic trend in the development of materials science at the present stage is the transition from intuitive-empirical approach to evidence-based methods of “design” in material and workmanship of them knowledge-based engineering products. To the fore the problem of purposeful obtaining materials and products based on them, the management of their structure and properties through the use of basic scientific knowledge. One of the new approaches to solving this problem is based on the method of multifractal (MF) parameterization of the images of the microstructure. Practical utilization of parameterization in improving materials and processes allows to push the idea of applying the methodology applied to the iron-based alloys [1].

One of the most important in this regard is that of improving the strength properties of steels, including powdered ones. To solve this problem it is necessary to establish a correlation between the mechanical properties and microstructure parameters MF [2] of powder alloys and determination of the optimal composition of alloying elements using MF charts: ordering-uniformity.

In view of the above, for the improvement of the strength properties of powder alloys it is expedient to use MF-parameterization. As a cost-effective, accurate and rapid means of analysis of the structure of materials, the MF-parameterization can be used to identify regularities in the formation of the microstructure of steels and prediction of their mechanical properties. Harnessing the power of MF-parameterization [3, 7-10], subject to appropriate adaptation and to identify the necessary relationships that may increase the effectiveness of improving the properties of alloy powders for the manufacture of engineering products.

Material and Methods

In the studies to establish correlations among the multifractal parameters and conditions for obtaining images of the microstructure of carbon steels there were used photographs obtained by digital photography at various magnifications. Thin sections were prepared for photomicrography on samples of steel 10, 20 and 45 to the etching of thin aqueous solutions of nitric (2%), picric (5%) acids, as well as solutions of ferric chloride in hydrochloric acid.

When studying the relationship of multifractal parameters and properties of carbon and alloy steels there were used powder photographs obtained by digital photography at different magnifications.

For the preparation of powders of samples following particle-size composition: Fe – 45-160 micrometers, Cu – 70 micrometerss, Mo – 5 micrometers, Ni – 20 micrometers. In the manufacture of samples of powder steels molding was carried out under a specific pressure of 5.5 t / cm2 using a hydraulic press. Exposure during sintering was performed in an environment of dissociated ammonia according to the following program: 200 ° C – 1 hr 15 min, at 600 ° C – 1 hour, at 1150 ° C – 2 hours. Samples are interspersed with a mixture of alumina and 9.7% graphite. Resintering was performed at 1150 ° C for 2 hours. The main results are obtained using the methods of mechanical testing, metallographic analysis and multifractal parameterization [4-6].

The Basic Part

In this paper we studied the effect of the optical zoom photography. For calculations of the characteristics of order [delta]q = D1-Dq and homogeneity (fq) program multifractal analysis MFRDrom was used, developed by G.V. Vstovskii [3, 10]. Multifractal analysis was performed on the canonical spectra for type-busting scale Fe and variant generation measures for black pixels.

To assess the impact of the degree of increase in the multifractal parameters the following experiment was performed. By digitally photographing images of the microstructure there were obtained steels 10, 20 and 45 after etching a 2% solution of nitric acid in ethanol. Photographing each steel was performed at a magnification: × 50, × 100, × 200, × 500 and × 1000. Further, the images were subjected to software processing using software MFRDrom.

The values of the order parameter [delta]q = D1-Dq, designed for small q = {40; 50; 60} are practically the same at magnifications of × 50, × 100 and × 200. However, at higher magnifications (× 500 and × 1000) curves of order “frustrated” with an invariant sequence.

To determine the type of versatility found multi fractal dependency was calculated characteristics of ordering [delta]q = D1-Dq and homogeneity (fq) for the micro structure of the steel 20. Comparing the results of the multi fractal parameterization of steel structures 10 and 20, we can state the immutability of the general form and arrangement of curves of order [delta]q = D1-Dq. Found for Steel 20 dependencies [delta]q = f (q), as in the first case, respond well to a polynomial approximation curve of second order.

One can also talk about the approximate coincidence of the curves homogeneity (fq), which confirms the assumption of a relatively weak relationship homogeneity (fq) and zoom microstructure. The main result of the change of grade of steel was the vertical displacement of the graphs of both the characteristics of [delta]q, fq relatively similar curves plotted for steel 10.

As in the first two cases, the curves of order [delta]q = D1-Dq have a common (invariant) sequence of values that do not depend on an increase in the range × 50- × 200.

When comparing the data multifractal parameterization and mechanical tests were obtained according to linking ordering [delta]q and tensile strength alloys PK10-PK40.

The best results were a polynomial curve fitting second-order managed to get to [rho] = 7,2 • 103 kg / m3. When calculating the homogeneity fq, there were found remarkable properties of this parameter’s dependecy on the carbon content. These include quite a sharp change in the relationship C squared – fq, observed at a concentration of carbon more than 0.4 … 0.5%.

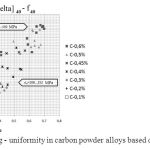

Figure 1 shows the [delta] – f diagram corresponding to the construction of the parameter q = 40 for the alloy density 7,2 • 103kg / m3. One of the observed properties of [delta]q-fq-diagrams proved distribution of the experimental points on separate compact areas of localization. All constructed diagrams clearly distinguished 3 such clusters of points, and each of them corresponded to a fixed interval strength [sigma] in.

In addition, each successive zone occupied a smaller area compared to the previous one, but some form of it was adequate. This feature allowed for the assumption of the fractal properties of [delta]q – fq -diagrams.

There was found an opportunity to determine the optimal content of alloying elements using the diagram: ordering – uniformity. Among the potential applications of the multifractal parameterization is of interest to optimize the composition of powdered iron-based alloys. This task today is relevant to engineering and other industries.

|

Figure 1. Diagram ordering – uniformity in carbon powder alloys based on iron, built for q = 40 |

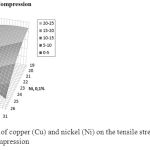

In this paper we analyzed the effectiveness of the methods of MF parameterization in improving the composition of the copper-nickel alloy powders. At the first stage the search for optimal composition of alloying elements was carried out according to traditional methods, by constructing a matrix of experimental design and finding the target response function. The content in the experimental samples of copper (Cu) and nickel (Ni) was varied in the range 2.5-3.0% and 2.0-2.5% respectively.

To examine the relationship of multifractal parameters of the micro structure and mechanical properties on the samples there were prepared Micro sections and then produced etching and photography micro structure. On the values that the tensile strength when tested in compression [sigma] received experimental points was found, the response function. Graphic representation of the corresponding surface shown in Figure 2.

|

Figure 2. Effect of concentration of copper (Cu) and nickel (Ni) on the tensile strength of the alloy PKN2D2M when tested in static uniaxial compression |

Calculation of Pearson’s possible to establish a fairly similar behavior σcomp strength and characteristics of the order [delta]40, [delta]60, [delta]100, as well as the hardness of HB and [delta]140.

Conclusion

The influence of the conditions for obtaining images of the microstructure (magnification, the type of etchant, plane grinding) on multifractal parameters [delta]q, fq was studied. The conditions for image acquisition, excluding distortions MF parameters were revealed. For alloyed steel powder there was found the relationship between the order parameter [delta]40, [delta]60, [delta]100 and a compressive strength of [sigma], ordering [delta]140 and the hardness of HB, as well as between the characteristics of homogeneity f160 and f200 and concentrations alloying elements. We propose a method for indirect evaluation of mechanical properties, which allows to reduce costs compared to mechanical tests.

Summary

Improvement of the strength properties of copper-nickel powder steels was conducted using fractal (periodic) chart properties: ordering-uniformity. Harnessing the power of MF-parameterization provides increased strength characteristics up to 8-10% and significantly (up to 40%) to reduce the cost of optimization by reducing the number of experimental studies.

References

- Galimov E.R., Kudrin A.G. and A.S. Maminov, 2009. Using the method of multifractal parameterization problems in metallurgy powder steels. Scientific and technical statements SPbSPU, 4-2 (89): 26-30.

- Galimov E.R., Kudrin A.G. and A.S. Maminov, 2009. Influence zoom results multifractal parameterization microstructure of steels. Bulletin of the Kazan State Technical University A.N. Tupolev, 4 (56): 40-42.

- Vstovskii, G.V., A.G. Kolmakov and I.G. Bunin, 2001. Introduction to the multifractal parameterization of material structures. Izhevsk Research and Publishing Center “Regular and Chaotic Dynamics”, pp: 116.

- Galimov E.R., Ablyasova A.G., Maminov A.S., Kuryntsev S.V. and A.V. Belyaev, 2011. Prediction of mechanical properties of welded joints. Journal on International Scientific Publication: Materials, Methods & Technologies, 5(3): 39-49.

- Shveyov A.I., Shafigullin L.N., Gumerov A.F., Gumerov M.I., Galimov E.R., Belyaev A.V. Parameterization of Microstructures in Material Science and Material Technology. World Applied Sciences Journal 26 (9): 1258-1260, 2013.

- Anvarov, A.V., 2006. Methods of assessing the resource safe use of chemical products based on methodology multifractal parameterization, Ph.D. thesis, Kazan State Tech. Univ.

- Vstovsky, G.V., I.G. Bunin and A.G. Kolmakov, 1996. Information-theoretic Interpretation of Multifractal Formalism and Analysis of Metallic Fracture Surfaces. Engineering Materials Advisory Services Ltd. (EMAS), 1(2): 301-306.

- Vstovskii, G.V., 2002. Elements of Information Theory. Moscow: MGIU, pp: 260.

- Kolmakov, A.G., I.G. Bunin, G.V. Vstovsky, 1997. Investigation of Effect of Surface Decarburisation on Mechanical Properties of Molybdenum using Multifractal Formalism. International Journal of Offshore and Polar Engineering (ISOPE), 1(7): 44-47.

- Shveyov A.I., Ganiev M.M., Shafigullin L.N., Kurin S.V., Gumerov M.I., Galimov E.R., Belyaev A.V. Special Aspects of Preparation of Microstructure Images for Parametrization of Welding Joints. World Applied Sciences Journal 29 (4): 560-563, 2014.