Bajrang C.1, G. Vaira Suganthi2,3, R. Tamilselvi3, M. Parisabeham3 and A.Nagaraj3

1BS-MS Student, Indian Institute of Science Education and Research, Mohali, India

2Department of CSE, Sethu Institute of Technology, Tamilnadu, India

3Department of ECE , Sethu Institute of Technology, Tamilnadu, India

DOI : https://dx.doi.org/10.13005/bpj/1840

Abstract

Conversion of human mechanical energy to usable electrical energy may seem like something from science fiction for the earliest generation of electronical engineers. But owing to the recent scientific advancements, it is no longer just a fiction but a reality. Researchers are working hard-time to improvise this idea by making attractive advancements in the field every day. This particular advancement gets much attention because it seems to be the most likely candidate to limit the usage of batteries, which have become a paradigm in the commercial world. Harvesting human energy can eliminate the limitations of scientific advancements in the portable and implantable devices due to the usage of batteries as their power source. There are several methods by which energy can be harvested from human activities, including but not restricted to thermoelectric generation, piezoelectric generation and triboelectric generation. These biomechanical phenomena can be tamed for commercial electricity usage under various circumstances. This paper provides a detailed review on these methods and the advancements made so far by researchers all around the globe.

Keywords

thermoelectric generation; piezoelectric generation; triboelectric generation

Download this article as:| Copy the following to cite this article: Bajrang C, Suganthi G. V, Tamilselvi R, Parisabeham M, Nagaraj A. A Systematic Review of Energy Harvesting from Biomechanical Factors. Biomed Pharmacol J 2019;12(4). |

| Copy the following to cite this URL: Bajrang C, Suganthi G. V, Tamilselvi R, Parisabeham M, Nagaraj A. A Systematic Review of Energy Harvesting from Biomechanical Factors. Biomed Pharmacol J 2019;12(4). Available from: https://bit.ly/36vHLJF |

Introduction

Technologies and scientific advancements continue to boon since the Industrial revolution. From old age factory equipment to modern smart electronics, technological advancements have developed so rapidly even surpassing their commercial counterparts. To run those technologies, it is inevitable to have an energy source which supplies energy to the devices. For quite a few years now, a paradigm is being observed within the commercial communities regarding that energy source: Battery. Batteries have been used by people for more than a century to provide energy to the devices. Though the batteries are commercially favoured by many, it is also undeniably true that batteries are limiting the improvements in many electronic devices especially, the portable routine devices like smart phones and health care devices. To counter that, scientists today are battled to harvest energy from our human body to model revolt against the existing paradigm. By harvesting energy from human body, we can limit the usage of batteries and thus enable more improvements to the devices. Recently, the amount of attention among researchers to harvest energy from human beings has grown so rapidly. The main reason so as to why can be explained by the limitless possibilities of improvements it can bring to the scientific world and to the civilization in general.

Power can be harvested from a person by various means. Almost every mechanical work a person does can be harnessed to some form of usable energy, let alone the body heat and biochemical processes of a human body. Such mechanical actions include walking, standing, sitting, jumping, chewing, etc. These actions can be converted to a utilizable power source by sensors like piezoelectric generators and triboelectric generators. Body heat can be used to obtain a form of electricity called thermoelectricity as well. Although there are many methods to producing these alternatives to battery, this paper will concentrate on exploring the possibilities paved by the improvements in the fields of piezoelectricity, triboelectricity and thermoelectricity.

Methods of Energy Harvesting

As M. Loreto Mateu Sáez presented, Energy harvesting methods can be distinguished into two:

Active Powering

Passive Powering

Active Powering

Active powering refers to the kinds of methods in which the user of the device has to perform a specific task or an action to obtain electricity. [1]

Passive Powering

Passive powering refers to the kinds of methods in which the user of the device does not have to do any specific task or action to obtain electricity i.e. the power can be harvested from everyday routine tasks like human motion and body heat. [1]

Many researchers are not keen on active powering of devices as it provides no benefit or significantly less when compared to its passive counterpart. So, this paper will only focus on the passive powering of devices.

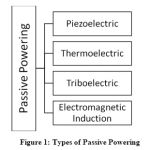

The following diagram categorizes the ways by which the passive powering can be possible:

|

Figure 1: Types of Passive Powering |

As the chart in Figure 1. Indicates, normal human body motion can be harvested as usable energy from processes of Piezoelectricity and triboelectricity. Human body heat can be harnessed as a power supply using the concept of thermoelectricity.

Piezoelectricity

The word ‘Piezo’ is a Greek word, referring to ‘Pressure’. The piezoelectric effect was first observed by Carl Linnaeus and Franz Aepinus [2] but was not clearly explained till the discovery of the same by Jacques and Pierre Curie in March of 1880. [3] The two observed the effect in zinc blende, sodium chlorate, boracite, tourmaline, quartz, calamine, topaz, tartaric acid, cane sugar, and Rochelle salt. [4]

The phenomenon of ‘Piezoelectricity’ is a molecular phenomenon which can be macroscopically observed to be the production of electrical potential when certain substances are deformed. [2] Such substances are called ‘Piezoelectric devices’.

Piezoelectric materials exist in various forms namely crystalline, polycrystalline ceramics, polymeric composites, glass and thin films on substrate. The non-crystalline materials are subjected to a process called ‘Poling’ which lines up the dipoles in presence of an electric field. A polar axis is thus created in polycrystalline materials which may exhibit piezoelectric properties. [5]

Examples of each form

Crystalline Piezoelectric material – Quartz

Polycrystalline Ceramic Piezoelectric material – Lead Zirconate Titanate (PZT)

Glassy State Ceramic materials – Ba2Ge2TiO8 (BGT) and B2Si2TiO3 (BST)

Polymeric piezoelectric material – Polyvinylidene fluoride (PVDF)

When stress T is applied on a material causing a strain S, the relations between the two can be written as [5]

Where c is the elastic stiffness constant and s is the compliance.

For a Piezoelectric material, the stress T will cause a polarisation of

![]()

where d is the piezoelectric strain constant. The dielectric displacement in presence of a stress T can be given by [5]

![]()

Where e is the dielectric constant. As most crystals are anisotropic, stress in one direction can cause strain in other directions too. So, the situation is represented in tensor notation based on three convenient orthogonal axes.

So, the relation becomes

![]()

where i = 1, 2, 3, and k = 1, 2, 3,…6

The strain can similarly be represented by

![]()

If the matrix is known, the polarisation for a given stress can be calculated. Constant can be found experimentally for a crystal of given symmetry. [5]

Antonino Proto and Marek Penhaker et al. presented two piezoelectric materials – Ceramic PZT and polymeric PVDF and compared the power outputs of the two materials. By placing the PZT and PVDF inside a tight wearable suit in close proximity to the main human body joints, neck, shoulder, elbow, wrist, hip, knee and ankle, kinetic energy was harvested. The transducers have to be kept in close contact to the body to work at their prime.

The following results were obtained

For a single transducer for a joint, the power output was 2-46 microW/cm^3.

For both transducers for a joint, the power output was 6 – 74 microW/cm^3.

The conclusion was that although PZT delivers more power output, PVDF is more comfortable as a product because PDVF can adequately follow the body segment movements. [6]

Zhixiang Li, Gongbo Zhou et al presented their study on the power generation capacity of piezoelectric energy harvesters (PEHs) with different fixation modes and adjustment methods. A piezoelectric ceramic plate (PCP) was used in supported beam fixation mode and cantilever beam fixation mode. Analyses was done using finite element simulations and experiments, and by adjusting the natural frequency of PCP. The experimental results showed that:

The supported beam fixation mode was more suited where the exciting frequency exceeds 50 Hz, while the cantilever beam fixation mode with exciting frequency below 50 Hz. The power was generated by a PCP in the former was higher than that in cantilever beam fixation mode. The conclusion was that by adjusting the mass of the block placed on the PCP, a greater change of its natural frequency was observed than when changing the length-width ratio. [7]

J.S. Partridge and R.W.G. Bucknall presented their work about the limitations for the production of electrical energy by walking. It was discovered that for an average person, on a level ground, up to 5 J/step can be generated. But walking up the stairs reduced and down the stairs increased the potential. A normal person can offer only a limited potential for energy harvest owing to the requirements of the human body to perform the routine functions mandatory for survival and the process of mechanical work costs significant losses. So, for walking, only a small fraction of the mechanical energy is available as harvestable energy. Although the obtained energy was not much, a huge amount of estimated potential of 900 MWh/day can be calculated when including a number of people, in the UK. [8]

Designed by Kimiko Ryokai, Peiqi Su, et al, EnergyBugs are energy harvesting wearables with features that invite children to move their bodies to generate tiny yet considerable quantities of electricity. EnergyBugs convert children’s kinetic energy to usable electrical energy and let children power a specially designed LED. So, the EnergyBugs convert the electrical energy to a tactile object that the children can manipulate. Two studies were conducted with 34 elementary school children; the results have revealed that the children perceived and negotiated the use of their personally harvested energy with other children by developing emotional connections to energy. Particularly, moving their bodies to generate energy fascinated the children to actively ask more questions about energy. [9]

The EnergyBugs system has two parts: the energy harvesting ‘Bugs’ and ‘Lamp’. The Bugs are wireless self-powering units with dual energy generators. The Bug consists of two energy harvesting methods:

The electromagnetic method

The piezoelectric method

The piezoelectric energy harvester contains two piezo disks that serve as sensors. The voltage output of one disk triggers a 10mm white LED as the other disk senses the user movement data. [9] The electromagnetic part will be dealt with in later paragraphs.

Xian-Hao Jia, Na Gao et al proposed an idea, floating piezoelectric microphone for implantable middle ear microphone. They made a piezoelectric sensor which is driven by the acoustic vibration of the ossicles for an implantable cochlear implant. Its frequency response was found using invitro testing of fresh cadaveric heads. The microphone was attached to the incus by a titanium clip or placed in the tympanic cavity and was stimulated with tones of multiple frequencies. And they observed that the piezoelectric microphone can pick up the vibration and convert it to electrical signals. [10]

Triboelectricity

The word ‘tribo’ in ‘triboelectricity’ means ‘friction’. Triboelectricity is the type of electricity produced when a surface of a material gets in contact with another.

The history of triboelectricity dates back 25 centuries ago when two materials are rubbed together, electrostatic charges are formed in the materials. Later in the 18th century, Charles Dufay named the two kinds of electricity produced by friction, vitreous and resinous which were then called negative and positive charges by Benjamin Franklin. [11] Further advancements were made in the subject among which the works of Michael Faraday, Coulomb, Maxwell, Tesla, Volta, Kelvin, Rutherford and Bohr were the most important. [12]

In 1757, J.C. Wilcke made a list of triboelectric materials (Shown in Figure 2.) and arranged them into a triboelectric series [13] (although the term ‘triboelectric series’ (TS) was coiled by Shaw in 1917 [14]). In the TS, the materials are arranged in a single vertical column. The ones at the bottom of the list obtain negative charge when they are rubbed with those that are above them. [12]

The triboelectric nanogenerator (TENG) is a simple, cost-effective and robust approach for self-powered systems made by Weiqing Yang, Jun Chen, et al. Generally, the power output is low but this paper presents a TENG with improved output current due to integrated rhombic gridding. They hybridised the contact-separation mode and sliding electrification mode among nanowire arrays and nanopores fabricated onto the surfaces of two contact plates. Production of an open-circuit voltage of up to 428 V and a short circuit current of 1.395 mA with peak power density of 30.7 W/m^2 was observed. A self-powered backpack (2kg) with 10.62% efficiency was developed with TENG. It directly powers 40 commercial LEDs simultaneously. The integrated rhombic gridding based TENG provides 2n^2 unit cells electrically connected in parallel, which is able to enhance the result. [15]

![Figure 2: Triboelectric series obtained from [14]](https://biomedpharmajournal.org/wp-content/uploads/2019/12/Vol12No4_Sys_Baj_fig2-150x150.jpg) |

Figure 2: Triboelectric series obtained from [14] |

Sen-Yeu Yang, Jian-Fu Shih et al selected two polymer materials (PDMS and PET) as triboelectric layers in conjunction with plastic metal (PM) films as conductive layers to make a high flexible electrode. The PM material was made by mixing Gallium-Indium liquid metal and a gaze powder. The results showed the superior characters of the flexible electrodes i.e. large bending angle (≥180°), small curvature radius (≤1 mm), and stable conductivity. This triboelectric generator could generate an output voltage of 80 V and current of 37.2 μA. [16]

Thermoelectricity

Thermoelectricity is defined as the kind of electricity which can be produced from the temperature difference observed between two materials, which in our case would be human body and the environment.

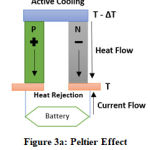

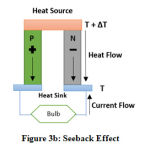

Thermoelectricity was first observed by Thomas Seeback in 1821 when he found that the circuit made of dissimilar materials at different temperatures deflected the compass needle. This was due to an induced thermoelectric current which deflected the magnet by Ampere’s law. This effect was called ‘Seeback effect’ (Figure 3b.). [17] The term ‘thermoelectric effect’ was itself coined later by H. Oersted who continued further in Seeback’s works. [18] Opposite to the Seebeck effect, Peltier observed that there is heating or cooling at an electrified junction of two different conductors. This was called the ‘Peltier Effect’ (Figure 3a.). [19][19]

|

Figure 3a: Peltier Effect |

|

Figure 3b: Seeback Effect |

ZT is defined as the thermoelectric performance.

![]()

For higher ZT, both Seeback coefficient (α) and electrical conductivity (σ) must be large and Thermal conductivity (κ) must be low the maintain the temperature difference producing Seebeck coefficient (α). [20]

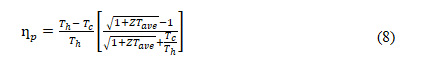

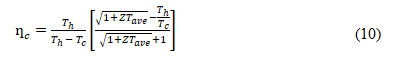

The power generation efficiency as a function of average ZTave can be given with the following relationship [21]

where ZTave is the average of both n-type and p-type legs, the ZTave per leg is averaged over the ZT curve between Th and Tc which is temperature dependent. Here, Th is the hot end and

Tc is the cold end [21]

The thermoelectric cooling efficiency ηc can be given by the following relationship [21]

The Peltier effect is used for thermoelectric cooling, which are used in electronic equipment for military usage.

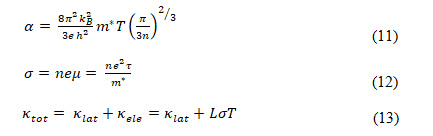

To get higher ZT, both Seebeck coefficient (α) and electrical conductivity (σ) should be large but thermal conductivity (κ) should be minimized. But according to the Wiedemann–Franz law, the electronic part of thermal conductivity (κ) is proportional to electrical conductivity (σ). Also, simultaneous increment of α and σ is limited by the Pisarenko relation.[22]. The relationships of these parameters can be put forth as [23]

where kB is the Boltzmann constant, m* is the density of states effective mass, h is the Planck constant, n is the carrier concentration, e is per electron charge, μ is the carrier mobility, τ is the relaxation time, κtot is the total thermal conductivity, κlat is the lattice thermal conductivity, κele is the electronic thermal conductivity, and L is the Lorenz number. [19]

Vladimir Leonov, Tom Torfs et al used hybrid wearable energy harvesters consisting of a thermoelectric generator (TEG) and photovoltaic (PV) cells to power the two autonomous devices: an electroencephalography (EEG) system and an electrocardiography (ECG) system in a shirt. The chosen hybrid for the EEG shirt included the PV cells covering the outer surface of radiators of a TEG. For the ECG shirt, thermoelectric modules are the main power supply while PV cells are used as standby power. Using these hybrid devices, the conclusion that the wearable energy harvester should be preferably hybrids of PV cells and TEGs. TEGs work well in the cold while PV cells outwit them in the hot. [24]

L.Francioso, C. De Pascali et al, made thermoelectric pastes based on Sb, Bi, Te powders to fabricate a flexible thermoelectric generator. Finite Element method simulations were used to finalize the TEG design to match thermal resistances of the human body to maximise its efficiency. The thermopile used by them is made by 450 couple of p – Sb2Te3 and n – Bi2Te3 deposited by coating into vertical parallel cavities of a patterned polydimethylsiloxane through hole layer. The legs were of 1.5 mm diameter and 2.5 mm height and the p-n couple was connected by printed silver contact. After testing, they concluded that a Seebeck coefficient of approximately 75 μV/K for p-n couple would be measured. [25]

Yang Yang, Guo Dong Xu et al developed a prototype which consisted of an implanted TEG and a specific boost circuit. A boosted circuit with a highly integrated DC/DC converter was used to stabilize the energy output and to improve the voltage output for the implanted TEG. From experiments, such combination was capable of supporting a clock circuit in vivo rabbit whose power consumption is higher than ordinary pacemakers. [26]

Other form – Electromagnetic Induction

Electromagnetic force is one of four fundamental forces of nature. The taming of such a fundamental force for daily usage came about after many important scientists and their contributions, with the most important ones being Faraday and Maxwell. Electromagnetic Induction is a phenomenon by which voltage is produced across a conductor in changing magnetic field.

Most energy harvesters involving electromagnetic induction consist of a permanent magnet and coils which act as alphabets for harvesting energy from the kinetic energy that our body produces while walking.

Longhan Xie and Ruxu Du stated that the human body contains copious chemical energy, of which only a part can be converted to about 200W of mechanical energy. The designed energy harvester consists of an eccentric rotor made up of a permanent magnet, electric steel and coils as stator. The rotor, as a simple pendulum can absorb the kinetic energy during walking. The permanent magnets on the rotor and the moving rotor can produce a changing magnetic field where electric coils can induce electric current. A torsion spring is also added onto the rotor such that the harvester works even when placed on a horizontal plane. The simulation showed that the harvester worn on wrist, with 40mm diameter and 50g weight, could generate dozens of milliwatts of electricity during normal walking. The conclusion was that the total mass, effective radius of the rotor, the arm swing frequency and amplitude were very important to the power output. The designed harvester can be served as a middleware to portable electronics. This energy harvesting technique can also be used to extract kinetic energy from other kinds of movement. [27]

The electromagnetic energy harvester in an EnergyBug has a neodymium magnet inside a clear acrylic tube in the middle of the box. Every tube has two 1500-turn coils: one, to generate usable energy to power the lamp; the other, to power the whole circuit. One coil with a 5494 surface Gauss neodymium magnet generates approximately 9.5 mW. This energy is stored in a 0.6 Farah super capacitor and in a 0.4 Farah super capacitor. [9]

Discussion – Comparisons and Developments

As mentioned, energy can be harvested from human body and human activities by various methods and forms. We saw the pros of every method above. So, it is noticeable that not all forms and methods produce the same quantity of power output. Comparison of these methods and forms becomes inevitable in order to determine which method or form produces the most beneficial output.

Raziel Riemer and Amir Shapiro stated that for a device that uses centre of mass motion, the maximum amount of energy that can be harvested is approximately 1 W per kilogram of device weight. The research, which was carried on a person of 80 kg, found that the knees and ankles produced the most power i.e. 34 W and 2 W respectively, when walking at 4 km/h. The results also suggested that a lightweight mechanical design is needed to obtain energy from the lower limbs effectively. [28]

Eliran Schertzer and Raziel Riemer, in their work, compared the advantages of harvesting biomechanical energy against conventional carrying. The case study concluded that to be considered over batteries, the harvesting devices on ankle, knee or back would need walking for 227 hours, 98 hours or 260 hours respectively. This would be preferred over batteries weighing 6.81 kg, 5.88 kg, 2.6 kg respectively. For the harvesting devices to be advantageous with less than 25 hours walking, developments in future should be based on light devices (less than 0.2 kg). [29]

Sara Khalifa, Mahbub Hassan et al, showed in their experimental study, the power consumption by the accelerometer and that it is a major blockage for realizing Human Activity Recognition (HAR) in self-powered wearable devices. By removing accelerometer, HAR from Kinetic Energy (HARKE) only consumes a fraction of the energy consumed by the accelerometer based HAR. This finding will allow for a new direction of research and development in realizing self-powered devices for the future Internet of Things. [30]

Paul D. Mitcheson, reviewed multiple choices for human energy harvesting to find the power availability for harvester-powered body sensor networks and found that inertial kinetic energy harvesting devices and thermoelectric devices were on the lead. A Comparison of these devices as a function of generator volume while walking and running was done. The paper concluded by saying that when running, the thermal device can was effective against kinetic energy device and that when walking, it was able to produce its highest energy density. [31]

Conclusion

Energy harvesting from human body is one of the most sought-after subjects by the people of scientific and engineering communities. It can be said so by analysing the improvements and stalls in the growth of technologies which involve supplying power with batteries. Batteries limit the possibility for more improvements in technology as well as it defines the size of the mobile device which cannot further be reduced. So, by eliminating such a limitation, the world can enter a new paradigm of energy harvesting and supplying with new possibilities and endless technological innovations.

In this paper, we have reviewed the three basic methods or forms of energy harvesting i.e. Thermoelectricity, Piezoelectricity and Triboelectricity, and the improvements, so far done, in the respective forms or methods. Further, we have also dealt about Electromagnetic Induction which is other way of harvesting energy from human movements. It can be concluded that by proper implementation and innovation, batteries can be gotten rid of the world to open the new era of battery-less mobile devices and technologies.

References

- Loreto Mateu Sáez and Francesc Moll Echeto, “Energy Harvesting from passive Human Power”, PhD Thesis, 2004.

- https://publish.illinois.edu/npre201piezo-fall2012/history-background/

- http://applied-piezo.com/short-history-of-piezoelectricity/

- Warren P. Mason, “Piezoelectricity, its history and applications”, The Journal of the Acoustical Society of America, 1981.

- Ram Prakash Singh, “Piezoelectric Polymers”, IETE Technical Review, 2015.

- Antonino Proto, Marek Penhaker et al, “Measurements of Generated Energy/Electrical Quantities from Locomotion Activities Using Piezoelectric Wearable Sensors for Body Motion Energy Harvesting”, Sensors, 2016.

- Zhixiang Li, Gongbo Zhou et al, “A Study on the Power Generation Capacity of Piezoelectric Energy Harvesters with Different Fixation Modes and Adjustment Methods”, Energies, 2016.

- S. Partridge, R.W.G. Bucknall et al, “An Analysis of the energy flow and energy potential from human energy harvesting with a focus on walking”, Cogent Engineering, 2016.

- Kimiko Ryokai, Peiqi Su, et al, “EnergyBugs: Energy Harvesting Wearables for Children”, CHI, 2014.

- Xian-Hao Jia, Na Gao et al, “A new floating piezoelectric microphone for the implantable middle ear microphone in experimental studies”, Acta Oto-Laryngologica, 2016.

- P. Olenick, T. M. Apostol, D. L. Goodstein, “Beyond the Mechanical Universe: from Electricity to Modern Physics,” Cambridge University Press, 1986.

- Fernando Galembeck, Thiago A. L. Burgo, et al, “Friction, Tribochemistry and Triboelectricity: Recent Progress and Perpectives”, RSC Advances, 2014.

- E. Shaw, Proc. R. Soc. Lond. Ser. A, 1917, 94, 16.

- F. Diaz, R. M. Felix-Navarro, Journal of Electrostatics, 2004, 62, 277.

- Weiqing Yang, Jun Chen, et al, “Harvesting Energy from the Natural Vibration of Human Walking”, ACS Nano, 2013.

- Sen-Yeu Yang, Jian-Fu Shih et al, “Development of high-flexible triboelectric generators using plastic metal as electrodes” Applied Physics A, 2017.

- http://www.thermoelectrics.caltech.edu/thermoelectrics/history.html

- http://kryothermtec.com/historical-background.html

- Xiao Zhang, Li-Dong Zhao, “Thermoelectric materials: Energy conversion between heat and electricity”, Journal of Materiomics, 2015.

- Q. He, M.G. Kanatzidis, V.P. Dravid, “High performance bulk thermoelectrics via a panoscopic approach”, Mater Today, 2013.

- H. Yang, “Special section papers on thermoelectric materials and applications”, J Electron Mater, 2007.

- Dresselhaus, H. Linke, et al, “Overview of thermoelectrics for thermal to electrical energy conversion”, Nobel symposium 153: nanoscale energy converters, 2013.

- J. Snyder, E.S. Toberer, “Complex thermoelectric materials”, Nat Mater, 2008.

- Vladimir Leonov, Tom Torfs et al, “Hybrid Thermoelectric–Photovoltaic Generators in Wireless Electroencephalography Diadem and Electrocardiography Shirt”, Journal of Electronic Materials, 2010.

- Francioso, C. De Pascali et al, “PDMS Template Generator for Wearable Thermoelectric Energy Harvesting Applications”, Springer, 2018.

- Weiqing Yang, Jun Chen, et al, “Harvesting Energy from the Natural Vibration of Human Walking”, ACS Nano, 2013.

- Longhan Xie and Ruxu Du, “Harvest human kinetic energy to power portable electronics”, Springer Journal of Mechanical Science and Technology, 2012.

- Yang Yang, Guo Dong Xu et al, “A Prototype of an Implantable Thermoelectric Generator for Permanent Power Supply to Body Inside a Medical Device”, Journal of Medical Devices, 2013.

- Eliran Schertzer and Raziel Riemer, “Harvesting biomechanical energy or carrying batteries? An evaluation based on a comparison of metabolic power”, Journal of Neuroengineering and Rehabilitation, 2015.

- Sara Khalifa, Mahbub Hassan et al, “Energy Harvesting Wearables for Activity-Aware Services”, IEEE Computer Society, 2015.

- Paul D. Mitcheson, “Energy Harvesting for Human Wearable and Implantable Bio-Sensors”, IEEE EMBS, 2010.