Fariborz Vafaee1, Farnaz Firooz1, Bijan Heidari1, Masoumeh khoshhal2, Farnoush Fotovat2 and Hanif Allahbakhshi2

1Department of Prosthodontics, Faculty of Dentistry, Hamadan University of Medical Sciences, Hamadan, Iran.

2Department of Prosthodontics, Faculty of Dentistry, Kashan University of Medical Sciences, Kashan, Iran.

Corresponding Author E-mail: h.allahbakhshi@yahoo.com

DOI : https://dx.doi.org/10.13005/bpj/1080

Abstract

The aim of this study was to compare flexural strength and fatigue resistance of 2 nanoceramic composite resin CAD/CAM blocks and a glass ceramic material. In this experimental study, resin nanoceramic blocks, Lava Ultimate, Vita Enamic and a lithium disilicate glass ceramic, IPS e.max CAD prepared on the basis of ISO 6872:2008. For 3 point bending test, 30 rectangular specimens prepared and loaded on a 10 mm span with crosshead speed of 1 mm/min. In fatigue resistance test, full crowns for mandibular second premolar were prepared for chewing cycle dynamic loading (250000cycles, 2 Hz, 100 N). Specimens survived from fatigue cycles, were loaded to fracture with a cross head speed of 1 mm/min. Failures in terms of fracture, crack formation and chipping were macroscopically recorded. The results were analyzed with one way ANOVA followed by multiple comparison Tukey HSD test. Also we used Chi Square for quantitative comparison after fracture of the specimens.The mean flexural strength was 139.921.2MPa for Lava Ultimate, 273.856.03MPa for IPS e.max CAD and 127.711.9 MPa for Vita Enamic. Significant differences were found between the groups (P<0.001).Mean fracture load after static loading was 1009.392.1 N for Lava Ultimate, 1698.5237.5 N for IPS e.max CAD and 733.2261.5 for Vita Enamic,which showed significant differences between the groups (p<0/001). Regarding to the macroscopically results after fracture load, there were no significant differences between the groups (p>0/05).The application of these nanoceramic resin composite materials for tooth-implant supported crowns seems promising.

Keywords

Ceramics; Computer-Aided Design; Fatigue; Composite resins

Download this article as:| Copy the following to cite this article: Vafaee F, Firooz F, Heidari B, khoshhal M, Fotovat F, Allahbakhshi H. A Comparative Study of Flexural Strength and Fatigue Resistance of 2 Nanoceramic Composite Resin Cad/Cam Blocks (Lava Ultimate and Vita Enamic) and A Lithium Disilicate Glass Ceramic (Ips E.Max Cad). Biomed Pharmacol J 2017;10(1). |

| Copy the following to cite this URL: Vafaee F, Firooz F, Heidari B, khoshhal M, Fotovat F, Allahbakhshi H. A Comparative Study of Flexural Strength and Fatigue Resistance of 2 Nanoceramic Composite Resin Cad/Cam Blocks (Lava Ultimate and Vita Enamic) and A Lithium Disilicate Glass Ceramic (Ips E.Max Cad). Biomed Pharmacol J 2017;10(1). Available from: http://biomedpharmajournal.org/?p=13998 |

Introduction

For decades, full coverage restorations have been used as the most common fixed prosthetic treatment to restore the function and appearance of the destroyed natural teeth [1]. Metal ceramic crowns have been considered the gold standard for full coverage restorations, due to their high strength, excellent fit and marginal integrity and long term survival rate [2,3]. However, biologic complications such as periodontitis [2,4], chipping and ceramic debonding [5] and lack of natural appearances are considered to be the problems of these restorations [6]. Therefore, the interest and demand from patient and clinician for biocompatible metal free restorations, has encouraged researcher to seek alternatives [1,7]. To fulfill these requirements, all-ceramic restorations with the advantages of soft tissue biocompatibility [8], color stability, improved wear resistance and excellent light transmitting properties [9] have been developed.

In 1965, McLean [10] introduced an alumina reinforced core ceramic, which was used for anterior teeth restorations. Meanwhile, CAD/CAM technology (computer aided design/computed aided) was introduced to dentistry in the 1980s [11, 12]. In principle, this technology have been developed for fully sintered ceramic blocks (hard machining), it has now been expanded to partially sintered ceramics (soft machining), that are later fully heat treated to ensure adequate sintering [13]. As a result, new generations of ceramic and composite materials for bi-layered and monolithic applications were developed. However, chipping of the bi-layered all-ceramic restorations [2,14] and bulk fracture of monolithic all-ceramic restorations, still demonstrate the most commonly reported laboratory and clinical complications [15-17]. All ceramic crowns have been used widely as a superstructure of dental implants in recent years [18,19]. There are two types of inherent flaws that compromise the ability of all-ceramic restorations to withstand occlusal forces: fabrication defects (internal voids, porosities, or microstructural features that arise during processing) and surface cracks (defects on the surface as a result of machining and grinding process) [20, 21]. Lithium disilicate glass ceramic (IPS e.max CAD) which investigated in this study is a CAD/CAM generated restoration [7]. Reparability of conventional ceramics in oral environment is often problematic. In comparison, composites can be repaired simply but they have poor mechanical characteristics and biocompatibility [22]. Therefore some authors are following more optimal restorations on the basis of modulus elasticity of composites similar to dentin and esthetic of feldespatic ceramics similar to enamel [23].

Recently, new generations of nanoceramic composite resin CAD/CAM blocks, Lava Ultimate (3M, ESPE, USA) nano ceramic particles embedded in a highly cured resin matrix and Vita Enamic (VITA Zahnfabrik, Bad Säckingen, Germany) polymer-infiltrated ceramic, have been introduced to dentistry, which are claimed to have higher flexural strength, fracture, fatigue and wear resistance, and beside natural looking appearances can be polished easily [24-26].

Therefore, the aim of this study was to compare flexural strength and fatigue resistance of 2 nanoceramic composite resin CAD/CAM blocks (Lava Ultimate and Vita Enamic) and a lithium disilicate glass ceramic (IPS e.max CAD) material.The null hypothesis was that there is no significant difference between the flexural of strength and fatigue resistance of the three groups.

Methods and Materials

In this experimental study, three CAD/CAM ceramic Materials were compared. Resin nanoceramic blocks, Lava Ultimate (3M, ESPE, USA) andVita Enamic(VITA Zahnfabrik, Bad Säckingen, Germany) and a lithium disilicate glass ceramic (IPS e.max CAD,IvoclarVivadent , Schann, Liechtenstein)as a control group were prepared for the flexural strength test according to the ISO 6872: 2008 [27] (Fig 1).

|

Figure 1

|

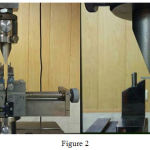

For 3 point bending test, 30 rectangular specimens (10 for each group) with the dimensions of ~14mm×4 mm×1.2 mm were prepared using a cutting machine (StruersMinitom, Willich, Germany ) at a rate of 250 rpm under water irrigation as instructed by the manufacturers [24]. Lava Ultimate and Vita Enamic just were polishedwith abrasive discs SiC paper 500, 1200 and 2400 # (LaboPol-1, Struers, Willich, Germany), while IPS e.max CAD specimens were fully crystallizedat 850ºC for 10 minutes in a ceramic furnace(VITA Vacumat 6000, Zahnfabrik, Bad Sackingen, Germany). Then the specimens were loadedby a universal testing machine (Zwick/Roell, Z050, Ulm, Germany) with crosshead speed of 1 mm/minon a 10 mm span. The loading apparatus was 4 mm in diameter (Fig 2).

|

Figure 2

|

In fatigue resistance test, titanium abutments (Implantium, Seoul, Korea) were used as die structure for ceramic crowns. They hada platform diameter of 4.5 mm, a height of 5.5mm and 1mm circular shoulder width. Occlusal thickness was 1.5mm which had the highest fracture strength regarding to other studies [27,28].

Titanium fixture analogs (Implantium, Seoul, Korea) (12×4.3 mm2) were embedded into the borehole (13mm depth, 4.5mm diameter) prepared from self-curedpolemethyl methacrylate blocks (Heraeus Kulzer, Dormagen, Germany). Then the abutments were screwed on the analogs with the torque of 30NCM and spray coated with titanium dioxide powder (Vivadent; Vita Powder Scan Spray, Bad Sackingen, Germany) to produce a white opaque surface for 3D scanning (inEOS Blue, Sirona,Bensheim, Germany).

Full crowns for mandibular second premolar (10 each group) were machined by in-lab system (MCXL, Sirona, Germany). Before cementation the crowns were air abraded using alumina powder (110 µm) from a distance of 5mm at 2 bar pressure [27]. Dynamic loading was performed by a universal machine (SD Mechatronik, Westerham, Germany). Internal surface of the crowns (except Lava ultimate) was first etched 60 seconds with 5% hydrofluoric acid, then rinsed, dried and silane (Monobond S, IvoclarVivadent, Bad Sackingen, Germany) was applied for 60 seconds.Crowns were cemented with resin based cement (Rely X U200, 3M ESPE, Minneapolis, USA) under 5-kg static load (Fig 3).

|

Figure 3

|

After careful removal of excess cement, load of 100 N was applied dynamically at 2 Hz for 100,000 cycles. Crowns received 1.5 mm laterally positioned axial loading from their buccal cusps. Aluminum foil was placed between the loading tip and the buccal cups for appropriate load distribution. The loading apparatus was 4 mm in diameter and 8mm in length (Fig 4).

|

Figure 4

|

Specimens survived from fatigue cycles, were loaded to fracture with a universal testing machine (Zwick/Roell, Z050, Ulm, Germany) at a cross head speed of 1 mm/min (Fig 5).

|

Figure 5

|

Failures in terms of fracture, crack formation and chipping were macroscopically recorded (Fig 6).

|

Figure 6

|

Differences between the means of the 3 groups were analyzed with one way ANOVA followed by multiple comparison Tukey HSD test. The normality of the groups evaluated with kolmogorov Smirnov test, also we used Chi Square for quantitative comparisonafter fracture of the specimens.

Results

For all the specimens, the flexural strength values were calculated with the mean values, standard deviation, maximum, and minimum displayed in Table 1. The kolmogorov Smirnov test showed the normality of the distribution (P>0.05).

The mean flexural strength value was 139.921.2MPa for Lava Ultimate, 273.856.03MPa for IPS e.max CAD and 127.711.9 MPa for Vita Enamic. Significant differences were found between the groups (P<0.001) by one way ANOVA [Tab 1].

Table 1: Descriptive statistics of flexural strength (MPa) for all ceramic groups

| Ceramic block | Minimum | Maximum | Mean ± SD | ANOVA analysis | |

| Lava Ultimate | 10 | 112.65 | 175.47 | 139.921.2 | |

| IPS e.max CAD | 10 | 158.27 | 352.96 | 273.856.03 | F=52.751

p-value>0.001 |

| Vita Enamic | 10 | 106.73 | 148.96 | 127.711.9 |

The Tukey HSD test showed that flexural strength of IPS e.max CAD is significantly higher than the two other ceramics (P<0.05) [Tab 2].

Table 2: Tukey HSD test for multiple comparisons between the 3 groups.

| Comparisons | Differences Mean | Std. Error | P-value |

| Lava Ultimate vs IPS e.max CAD | 133.844 | 15.778 | <0.001 |

| IPS e.max CAD vs Vita Enamic | 146.066 | 15.778 | <0.001 |

| Lava Ultimate vs Vita Enamic | 12.222 | 15.778 | 0.722 |

In fatigue resistance test, none of the specimens fractured after cyclic loading. Excessive wear just created in Vita Enamic specimens at the sliding area without any crack formation.

For all 3groups, the fracture strength values were calculated with the mean values, standard deviation, maximum, and minimum displayed in Table 3. The kolmogorov Smirnov test showed the normality of the distribution (P>0.05).

The mean fracture strength value was 1009.392.1 N for Lava Ultimate, 1698.5237.5 N for IPS e.max CAD and 733.2261.5 for Vita Enamic. Significant differences were found between the groups (P<0.001) by one way ANOVA [Tab 3].

Table 3: Descriptive statistics of fracture strength (N) for all ceramic groups.

| Ceramic block | Minimum | Maximum | Mean ± SD | ANOVA analysis | |

| Lava Ultimate | 10 | 854.69 | 1142.95 | 1009.392.1 | |

| IPS e.max CAD | 10 | 1396.91 | 2163.7 | 1698.5237.5 | F=55.613

p-value>0.001 |

| Vita Enamic | 10 | 476.8 | 1321.9 | 733.2261.5 |

The Tukey HSD test showed that fracture strength of IPS e.max CAD is significantly higher than the two other ceramics (P<0.05) [Tab 4].

Table 4: Tukey HSD test for multiple comparisons between the 3 groups.

| Comparisons | Differences Mean | Std. Error | P-value |

| Lava Ultimate vs IPS e.max CAD | 689.223 | 94.278 | <0.001 |

| IPS e.max CAD vs Vita Enamic | 965.258 | 94.278 | <0.001 |

| Lava Ultimate vs Vita Enamic | 276.035 | 94.278 | 0.018 |

Regarding to the macroscopically results after fracture load, type of the ceramic didn’t affect the failure modes, bulk fracture and chipping,and there were no significant differences between the groups (p>0/05) [Tab 5].

Table 5: Descriptive statistics of specimen failure modes after static loading.

| Type of ceramics |

Failure Modes |

||||||

| IPS e.max CAD | Lava Ultimate | Vita Enamic | |||||

| % | N | % | N | % | N | ||

| = 1/861 | 30% | 3 | 50% | 5 | 60% | 6 | Chipping |

| p-value=0/534 | 70% | 7 | 50% | 5 | 40% | 4 | Bulk Fracture |

Discussion

Based on the results of the present study, the null hypothesis was refuted. Statistically significant differences in flexural and fracture strength (P< 0.001) were observed between the 2 nanoceramic composite resin CAD/CAM blocks, Lava Ultimate and Vita Enamic, and a lithium disilicate glass ceramic (IPS e.max CAD) material, meanwhile they showed similar fatigue resistance after dynamic loading (250,000 cycles, 100N) with the survival rate of 100%. This result could be due to the modulus elasticity and adhesive cementation of these materials.

Although there are limitations with all these methods, the ISO standard test to determine thestrength of polymer based restorative materials remains the three-point bend test. Accordingly,the utilization of this method to test these new materials allows for easy comparative analysiswith other previously published results employing the same standard test methods.

Lava Ultimate was introduced into the dental market in 2012 and contains a blend of individually bonded nano-particles and nano-particles agglomerated in clusters, all embedded in a highly cross-linked polymer matrix. It contains a total nanoceramic filler content of approximately 80 % by weight [24]. Vita Enamic Launched onto the market in 2013 and has been called a “hybrid ceramic” or a polymer-infiltrated-ceramic network (PICN) [26].

The flexural strength of resinnanoceramic CAD/CAM blocks in our study was similar to the value reported by other researchers [28-30]. Although, our results showed that the mean value of just Vita Enamic met the claims of the manufacturer [26]. He and Swain [31,32] described the mechanical properties of these materials and found that they were very similar to natural dentin and enamel. Different results were found in the current study compared to other studies for flexural strength. Albero A et al [33] evaluated the characterization of a novel cad-cam polymer-infiltrated-ceramic-network. The results showed IPS e.max presented mechanical properties significantly betterthan other materials. However Vita Enamic had higher flexural strength than Lava Ultimate, but it was not significant. In accordance with the current study, Thornton I et al stated that in comparison to conventional resin composites, the presence of ceramic nano-particles in Lava Ultimate and Enamic did not greatly improve flexural strength of these materials. Their results showed that the flexural strentgh of Enamic was statistically significantly lower than that of Lava Ultimate, while the flexural modulus of Enamic was statistically significantly higher. Also, Kopfmann C et al [30] evaluated the comparison of filler morphology, mechanical strength and milling characteristics of 4 different CAD/CAM blocks for Sirona inLabMC XL milling system and showed that Coltene (Coltene AG) had the highest flexural strength, and Vita Enamic the Lowest one.

Titanium is a conventional material in posterior implant abutments due to its mechanical properties. Alsoin recent years, all ceramic crowns have been used as superstructures for posterior implants [18, 19]. Unilateral masticatory loads are variable between 216 to 847 N in posterior regions, but a maximum of 1031 N have been reported [29]. Aboushelib et al [34] evaluated the influence of cyclic fatigue on two resin infiltrated ceramics and three all-ceramic crowns manufactured using CAD/CAM technology. They stated that dynamic fatigue resulted in significant reduction of the initial fracture strength of the tested specimens.

Bulk fracture was the only failure mode reported for all tested monolithic CAD/CAM crowns. The differences in comparison to our study are probably due to the using of composite resin dies. Because when hybrid crowns are cemented to the dies with similar modulus elasticity, crown-die complex performs as an integrated unit, therefore they show higher fracture resistance. Fatigue behavior of IPS e.max CAD and core veneered zirconia evaluated in an invitro study [7] using step stress cycling fatigue test. This study reported that there were almost 90% of chipping in zirconia based ceramics (100,000 cycles , 200 N). In contrast, there was no fracture for IPS emax CAD after step stress fatigue (180,000 cycles , 900 N) similar to our study.

When looking at the spectrum of resin composite-ceramic, it becomes clear that the newnanoceramic resin composite materials do not behave similarly to the tested control, a lithium disilicate ceramic, IPS e.maxCAD, and actually behave as resin composites.

This invitro study had some limitations such as difficult simulation of the oral environment. Further in vitro and in vivo investigations are necessary to evaluate surface roughness, marginal integrity, reparability and milling accuracy of these new materials.

Conclusion

IPS e.max CAD exhibited higher values in flexural strength between the 3 groups. The others respectively were Lava Ultimate and Vita Enamic. Clinically it is demonstrated that IPS e.max CAD can tolerate higher values of mechanical loads until fracture.The flexural strength of Lava Ultimate and Enamic was greatly improved to levels not seen before in dental resin composites.Regarding to the mean fracture load of the 2 specimens that are higher than the mean fracture load suggested for posterior regions, the application of these nanoceramic resin composite materials for tooth-implant supported crowns seems promising. However, their consideration and clinical use in patients with high muscular and masticatory forces especially patients with bruxism and clenching, better to be similar to that of conventional dental CAD/CAM resin composites and be limited to inlay, onlay and veneer restorations.

References

- Dolan TA,Gilbert GH,Duncan RP, Foerster U. Risk indicators of edentulism, partial tooth loss and prosthetic status among black and white middle-aged and older adults. Community Dent Oral Epidemiol 2001; 29:329.

CrossRef - Pjetursson BE, Sailer I, Zwahlen M, Hämmerle CH. A systematic review of the survival and complication rates of all-ceramic and metal-ceramic reconstructions after an observation period of at least 3years. PartI: Single crowns. Clin Oral Implants Res 2007; 18(3):73–85.

CrossRef - Reitemeier B, Hansel K, Kastner C, Weber A,Walter M.H. A prospective 10-year study of metal ceramic single crowns and fixed dental prosthesis retainers in private practice settings. J Prosthet Dent 2013; 109(3): 149-155.

CrossRef - Lucas L.C, Lemons J.E. Biodegradation of restorative metallic systems. Adv Dent Res 1992; 6: 32-37.

CrossRef - Marklund S, Bergman B, Hedlund S.O,Nilson H. An intraindividual clinical comparison of two metal-ceramic systems: a 5-year prospective study. Int J Prosthodont 2003; 16(1): 70-73.

- Anusavice K.J. Recent developments in restorative dental ceramics. J Am Dent Assoc 1993; 124(2): 72-74, 76-78, 80-84.

CrossRef - Guess PC, Zavanelli RA, Silva NR, Bonfante EA, et al. Monolithic CAD/CAM lithium disilicate versus veneered Y-TZP crowns: comparison of failure modes and reliability after fatigue. Int J Prosthodont 2010; 23(5):434-42.

- Sjogren G, Sletten G,Dahl J.E. Cytotoxicity of dental alloys, metals, and ceramics assessed by millipore filter, agar overlay, and MTT tests. J Prosthet Dent 2000; 84(2): 229-236.

CrossRef - Gallucci G.O, Guex P, Vinci D,Belser U.C. Achieving natural-looking morphology and surface textures in anterior ceramic fixed rehabilitations. Int J Periodontics Restorative Dent 2007; 27(2): 117-125.

- McLean J.W,Hughes T.H. The reinforcement of dental porcelain with ceramic oxides. Br Dent J 1965; 119(6): 251-267.

- Manicone PF, Lommetti PR, Raffaelli L. An overview of zirconia ceramics: basic properties and clinical applications. Journal of Dentistry. 2007; 35(11):819–826.

CrossRef - Kelly JR, Denry I. Stabilized zirconia as a structural ceramic: an overview. Dental Materials. 2008; 24(3):289–298.

CrossRef - Denry I, Holloway JA. Ceramics for dental applications: A review.Materials 2010; 3:351–368.

CrossRef - Goodacre CJ,Bernal G,Rungcharassaeng K,Kan JY.Clinical complications in fixed prosthodontics. J Prosthet Dent 2003; 90:31–41.

CrossRef - Al-Amleh B, Lyons K,Swain M. Clinical trials in zirconia: a systematic review. J Oral Rehabil 2010; 37(8): 641-652.

CrossRef - Bindl A, Richter B,Mormann W.H. Survival of ceramic computer-aided design/manufacturing crowns bonded to preparations with reduced macroretention geometry. Int J Prosthodont 2005; 18(3): 219-224.

- Coelho PG, Silva NR, Bonfante EA et al. Fatigue testing of two porcelain–zirconia all-ceramic crown systems. Dent Maters 2009; 25(9):1122-1127.

CrossRef - Andersson B, Ödman P, Lindvall A-M, Brånemark P-I. Cemented single crowns on osseointegrated implants after 5 Years: Results from a prospective study on Cera One. Int J Prosthodont 1998; 11:212–218.

- Prestipino V, Ingber A, Kravitz J. Clinical and laboratory consideration in the use of a new all-ceramic restorative system. Pract Periodontics Aesthet Dent 1998; 10:567–575.

- Rosenstiel SF, Land MF, Fujimoto J: Contemporary Fixed Prosthodontics. St. Louis, MO, Mosby, 2016, pp. 774-804.

- Beier US, Kapferer I, Dumfahrt H. Clinical long-term evaluation and failure characteristics of 1,335 all-ceramic restorations. Int J Prosthodont 2012; 25(1): 70–78.

- Nguyen JF, Ruse D, Phan AC, Sadoun MJ. High-temperature-pressure polymerized resin-infiltrated ceramic networks. J Dent Res. 2014; 93(1):62-67.

CrossRef - Della Bona A, Corazza PH, Zhang Y. Characterization of a polymer-infiltrated ceramic-network material. Dental Materials. 2014; 30(5):564-9.

CrossRef - 3M ESPE internal data: Lava Ultimate CAD/CAM restorative technical profile. Available at: http://multimedia.3m.com/mws/Accessed July 11, 2014.

- Koller M, Arnetzl GV, Holly L, Arnetzl G. Lava ultimate resin nano ceramic for CAD/CAM: Customization case study. Int J Comput Dent 2012; 15(2):159-64.

- VITA internal data: Vita Enamic: the concept. Available at: http://vident.com/wp-content.

- ISO 6872: 2008, Ceramic materials,International Organization for Standardization.

- Awada A, Nathanson D. Mechanical properties of resin-ceramic CAD/CAM restorative materials. J Prosthetic Dent 2015; 114(4):587-593.

CrossRef - Stawarczyk B, Liebermann A, Eichberger M, Guth JF. Evaluation of mechanical an optical behavior of current esthetic dental restorative CAD/CAM composites. J MechBehav Biomed Mater 2015; 55:1-11.

CrossRef - Kopfmann C, Zweifel D, Böhner R. Comparison of filler morphology, mechanical strength and milling characteristics of different CAD/CAM blocks for Sirona inLab MC XL milling system. Available at: coltene.com. 2015.

- He L, Swain M. A novel polymer infiltrated ceramic dental material. Dent Mater. 2011; 27(6):527-34.

CrossRef - He L, Purton D, Swain M. A novel polymer infiltrated ceramic for dental simulation. J Mater Sci: Mater Med. 2011; 22:1639-1643.

CrossRef - Albero A, Pascual A, Camps I, Grau-Benitez M. Comparative characterization of a novel cad-cam polymer-infiltrated-ceramic-network. J Clin Exp Dent. 2015; 7(4):495-500.

CrossRef - Aboushelib MN, Elsafi MH. Survival of resin infiltrated ceramics under influence of fatigue. Dent Mater. 2016; 32(4):592-34.

CrossRef