Manuscript accepted on :October 11, 2017

Published online on: --

Abdalbaseet A. Fatalla1 , Manar E. AlSamaraay2

, Manar E. AlSamaraay2 and Raghdaa K. Jassim3

and Raghdaa K. Jassim3

1, 3Department of Prosthodontics, College of Dentistry, University of Baghdad.

2M.Sc Student, Department of Prosthodontics, College of Dentistry, University of Baghdad.

Corresponding Author E-mail: Abdalbasit@codental.uobaghdad.edu.iq

DOI : https://dx.doi.org/10.13005/bpj/1313

Abstract

Impairment in the material properties may reduce its service life and in turn create the need for its replacement. The aim of this study was to evaluate the effect of adding Polyamide-6 (Nylon-6) on the tensile strength, elongation percentage, tear strength, hardness and surface roughness of A-2186 RTV silicone elastomer before and after accelerated artificial aging. 120 samples were fabricated by the addition of 1% by weight PA-6 micro-particles powder to A-2186 platinum RTV silicone elastomer. Based on the pilot study, the 1% reinforcement reported improvement in tensile as well as tear strength among all other percentages (3% and 5%). The main study samples were divided into four (4) groups, each one containing (30) samples according to the conducted tests, i.e. tensile strength, tear strength, hardness test, and surface roughness except for the elongation percentage test which was measured concurrently with the tensile strength test. Then, each group was subdivided into three subgroups according to the artificial weathering environment (A. control before weathering, B. after 100 hours of artificial weathering, and C. after 200 hours of weathering) where n= 10. The samples were tested before and after artificial weathering, and the data were analyzed with a descriptive statistical analysis, one-way ANOVA, post-hoc LSD test and coefficient of determination. The addition of 1% by weight PA-6 micro-particles to A-2186 maxillofacial elastomer after 100 hours of aging resulted in a non-significant increase in the mean values of tensile strength, elongation percentage and tear strength (P>0.05) whereas a highly significant increase in hardness and surface roughness tests were found (P≤ 0.01). On the other hand, tensile strength, and tear strength were reduced non-significantly (P>0.05) after 200 hours of artificial aging while elongation percentage value witnessed highly significant reduction (P≤ 0.01). The hardness value continued to increase but in a non-significant manner (P>0.05) on the contrast to the surface roughness value which showed a highly significant increase (P≤ 0.01). Incorporation of PA-6 micro-particles prevents the silicone matrix from rapid degradation under artificial aging conditions and may result in an increase in the service life of the prosthesis.

Keywords

Polyamide; Room Temperature; Silicone Elastomer

Download this article as:| Copy the following to cite this article: Fatalla A. A, AlSamaraay M. E, Jassim R. K. Effect of the Addition of Polyamide (Nylon 6) Micro-Particles on Some Mechanical Properties of RTV Maxillofacial Silicone Elastomer Before and After Artificial Aging. Biomed Pharmacol J 2017;10(4). |

| Copy the following to cite this URL: Fatalla A. A, AlSamaraay M. E, Jassim R. K. Effect of the Addition of Polyamide (Nylon 6) Micro-Particles on Some Mechanical Properties of RTV Maxillofacial Silicone Elastomer Before and After Artificial Aging. Biomed Pharmacol J 2017;10(4). Available from: http://biomedpharmajournal.org/?p=17516 |

Introduction

Patients with facial defects may suffer from embarrassment and always feel constrained and diminished on both physical and psychological levels. Prosthetic restoration for patients suffering from facial deformities may work as a psychological therapy and considered satisfactory, allowing these individuals to integrate into society by being more confident through reestablishment of their self-esteem. However; in the presence of favorable circumstances, plastic repair performed on living tissues is much more desirable than the prosthetic restoration.1,2

Generally, the goal of prosthodontic rehabilitation is not expanded by the restoration of function and esthetic ; thus, a tremendous increase in using different types of maxillofacial materials is noticed to improve these goals.3,4 Silicone elastomer can be considered as the most appropriate material for fabricating facial prostheses; it gained a wide clinical acceptance due to its biocompatibility, low chemical reactivity, ease of manipulation, and optical transparency which facilitates the pigmentation of silicone for simulating skin tone.5 However, its mechanical properties do not fulfill the ideal requirements, resulting in a reduction in the clinical longevity of the prosthesis fabricated from this material. Hence, reinforcement of this material may become mandatory to overcome its deficiencies.6

A study by Gunay et al. (2008)7 reported improvement in the mechanical properties of A-2186 room temperature vulcanized (RTV) silicone elastomer especially the tear strength after being reinforced with tulle (Nylon). Moreover, various types of additives have been mentioned to be incorporated within the silicone matrix and to cause improvement in the mechanical and physical properties of the silicone base material.8,9,10

The aim of this study was to evaluate the effect of adding Polyamide-6 (Nylon-6) on the tensile strength, elongation percentage, tear strength, hardness and surface roughness of A-2186 RTV silicone elastomer before and after accelerated artificial aging.

Materials and Methods

This study investigated some mechanical properties of A-2186 Platinum RTV silicone elastomer (Factor II Inc., Lakeside, AZ, USA) before and after accelerated artificial weathering. Polyamide-6 (Nylon-6) micro-particles powder (average particle size 15-20 micron) (Goodfellow, Cambridge Limited, England) was used for reinforcement.

A specialized cutting of 4±0.05 mm, 2±0.05 mm and 6±0.05 mm thickness acrylic sheets (PT. Margacipta Wirasentosa, Indonesia) is performed by using a laser engraving cutting machine (JL-1612, Jinan Link Manufacture & Trading Co., Ltd., China) to prepare the mold parts. The depth of the mold cavity 2±0.05 mm or 6±0.05 thickness sheets corresponds to the thickness of the specimens to be fabricated for each conducted test while the 4±0.05 mm thickness sheets were used to make the bottom and cover parts.10

At first, a pilot study was conducted with 1%, 3% and 5% by weight of PA-6 which were added to the silicone and compared with the 0% PA-6 (control group). The PA-6 fillers were first weighted by electronic digital balance followed by the addition of accurate weight of silicone (part A) to prevent dispersion of the filler. The modified silicone was mixed by a vacuum mixer (Multivac 3, Degussa, Germany) (Figure 1) for 10 minutes; the vacuum was turned off for the first three minutes to avoid suction of the filler and then turned on for the rest of the 7 minutes at 360 rpm speed and a vacuum value of -10 bar. The silicone cross linker (part B) was added to the silicone base or the modified silicone (part A and PA-6) and mixed again in the vacuum mixer for 5 minutes to get a homogenous and free bubble mixture.11 The results revealed that 1% by weight PA-6 improved the tensile and tear strength of the tested silicone elastomer.

|

Figure 1: Vacuum Mixer

|

The mold was brushed with separating medium and left to dry then the silicone mixture was poured and the mold was closed with the aid of screws and G-clamps.10 According to manufacturer’s instruction, the silicone should be set aside for 24 hours at 23± 2°C and a relative humidity of 50%±10 % for complete setting (Figure 2).

|

Figure 2: silicone poured inside the mold

|

After polymerization, the silicone sheet 15×15 cm12 was separated from the mold cavity and was cut by a custom-made specimen cutting press (hydraulic jack of (3) tons capacity) (Lezaco, Syria) with the help of suitable cutting dies to ensure smooth cut surfaces (Figure 3).

|

Figure 3: silicone cutting dies and cutting press

|

A hundred and twenty specimens of the modified silicone were fabricated and divided into 4 groups according to the conducted tests (tensile strength and elongation percentage tests, tear strength test, Shore A hardness test and surface roughness test) with 30 specimens for each test except for the elongation percentage test which was calculated concurrently with the tensile strength test.

All specimens were visually inspected for surface irregularities, bubbles and internal defects.13 Group A specimens were stored inside a vaccine storage box (polar bag, china) for, at least, 16 hours of favorable conditions before testing,2,14,15 while specimens of group B and group C were stored until they were placed inside a Weather-Ometer machine (model QUV/spray, Q-Lab corp., USA). A digital indoor and outdoor thermometer with a hygrometer was used to record the temperature and humidity values inside the box.

Inside the Weather-Ometer, the specimens were assessed according to ASTM G154/7,16 each aging cycle was accomplished in 12 hours; the first 8 hours (light cycle) included irradiance of 340 nm and of 1.55 W/m2 and temperature of 60±3◦C. The following 4 hours representing dark cycle included irradiance of 340 nm and of 1.55 W/m2, 15 minutes of water spray system to induce thermal shock and, finally, 3.75 hours of condensation period at 50±3◦C temperature. All tensile strength, elongation at break and tear strength test specimens were tested with a computerized universal testing machine (WDW-20, Laryee Technology Co. Ltd., China) at 500 mm/min cross-head speed.9 Thirty specimens of Type 2 dumb-bell shape specimens were fabricated for tensile strength and elongation percentage tests, 10 specimens were used as control group and the other 20 were tested after 100 and 200 hours of accelerated artificial aging, respectively, according to ISO 37.17 Specimens were mounted in a computerized universal testing machine 25±0.5 mm apart.9 The tensile strength was calculated by the machine software according to the following equation:

Tensile strength=F/A

Where:

F: The maximum force recorded at break (N).

A: The original cross-sectional area of the specimen (mm2).

The elongation percentage test was calculated concurrently with tensile strength test according to the following equation:

Elongation at break= [(L-L0)/L0]×100

Where:

Lo: The original length (mm).

L: Extension at break (mm).

Thirty specimens of Type C, an un-nicked specimen with a 90° angle on one side and with tab end specimens, were fabricated for tear strength tests, 10 specimens were used as control group and the other 20 were tested after 100 and 200 hours of accelerated artificial aging, respectively, according to ASTM D624.18 Specimens were mounted in a computerized universal testing machine with a 30±0.5 mm distance apart.19 The tear strength was calculated by the machine software according to the following equation:

Tear strength=F/D

Where:

F: The maximum force required for specimen to break (KN).

D: The median thickness of each specimen (m).

Sixty specimens of 25×25×6 mm for Shore A hardness and surface roughness tests were fabricated,10,20 30 specimens for each test; 20 specimens were used as control group and the other 40 were tested after 100 and 200 hours of accelerated artificial aging, respectively, according to ISO 7619.21

For hardness test, shore A durometer was held vertically over a flat specimen supported by a rigid, flat surface. Five points were marked with a 6 mm distance apart between each other and the lateral margins of the test specimen; the average of these 5 readings was reported as the hardness value. Readings were taken after 1 second of stable contact over the specimen.9

The surface roughness test was carried out with the aid of a Portable digital roughness tester (Profilometer). The stylus of the device touches the surface of the specimen at three different points to obtain 3 readings. Later on, the mean value of the three readings was reported as roughness value.10,20

Furthermore, SEM as well as XRD analysis was performed on 4 samples, 2 for each test. One sample represents the silicone material before the addition of PA-6 fillers and the other one after the addition of the PA-6 fillers.

Results

SEM and XRD Analysis

SEM results of A-2186 platinum RTV silicone elastomer before and after the addition of 1% by weight PA-6 micro-particles powder are shown in (Figure 4). The results indicate well dispersion of the PA-6 micro-fillers into the silicone matrix (no agglomeration was seen).

|

Figure 4: SEM examination A: before the addition of PA-6, B: after the addition of PA-6

|

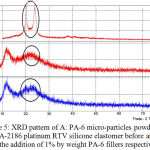

XRD diffraction peaks of PA-6 micro-particles powder and A-2186 platinum RTV silicone elastomer before and after the addition of 1% by weight PA-6 fillers are shown in (Figure 5).The results indicate the incorporation of the fillers into the silicone matrix.

|

Figure 5: XRD pattern of A: PA-6 micro-particles powder; B and C: A-2186 platinum RTV silicone elastomer before and after the addition of 1% by weight PA-6 fillers respectively

|

Tensile Strength, Elongation Percentage, Tear Strength, Shore A Hardness and Surface Roughness

Descriptive statistics, One-way ANOVA, coefficient of determination (R2) and % of variation values of the conducted tests were presented in tables 1-5. The LSD analysis is presented in tables 3-5.

In comparison to the control group, the tensile strength and tear strength test values were non-significantly increased (p>0.05) after 100 hours of artificial weathering and non-significantly decreased (p>0.05) after 200 hours of artificial aging as shown in tables 1 and 3.

Table 1: Descriptive statistics, One-way ANOVA, coefficient of determination (R2) and % of variation values of tensile strength test

| A | B | C | |||||||

| (control) | ( after 100 h) | (after 200 h) | ANOVA F- test | P. value | Compared groups | R2 | % of variation | ||

| N | 10 | 10 | 10 | A | B | 0.1339 | 13.39 | ||

| Mean | 5.744 | 5.946 | 5.505 | B | C | 0.0013 | 0.13 | ||

| SD | 0.6731 | 0.8087 | 0.9421 | 0.733 | 0.49 | C | 0.3283 | 32.83 | |

| Min. | 4.7 | 4.7 | 4.08 | NS | |||||

| Max. | 6.6 | 6.91 | 6.96 |

Table 2: Descriptive statistics, One-way ANOVA, LSD, coefficient of determination (R2) and % of variation values of elongation percentage test

| A | B | C | ANOVA F- test | P- value | Compared groups | P. values | LSD | |||

| N | (control) | ( after 100 h) | (after 200 h) | A | B | 0.056 | Sig. | |||

| Mean | 10 | 10 | 10 | B | C | 0 | NS | |||

| SD | 270.69 | 290.35 | 203.52 | 42.666 | 0 | C | 0 | HS | ||

| Min. | 21.43 | 21.643 | 23.018 | HS | R2 | HS | ||||

| Max. | 233.3 | 247.1 | 169.8 | A | % of variation | |||||

| 311.1 | 315 | 233.33 | B | B | 0.05 | |||||

| C | 0.108 | 5.017 | ||||||||

| C | 0.342 | 10.89 | ||||||||

| 34.222 |

Table 3: Descriptive statistics, One-way ANOVA, coefficient of determination (R2) and % of variation values of tear strength test

| A | B | C | |||||||

| (control) | ( after 100 h) | (after 200 h) | ANOVA F- test | P. value | Compared groups | R2 | % of variation | ||

| N | 10 | 10 | 10 | B | 0.015 | 1.587 | |||

| Mean | 20.986 | 21.19 | 20.122 | A | C | 0.028 | 2.822 | ||

| SD | 1.211 | 1.2662 | 1.8901 | 0.733 | 1.452 | B | C | 0.452 | 45.292 |

| Min. | 19.2 | 19 | 17.72 | NS | |||||

| Max. | 22.79 | 22.7 | 22.92 |

The percentage of elongation test values were non-significantly increased (p>0.05) after 100 hours of artificial weathering and significantly decreased (p<0.05) after 200 hours of artificial aging when compared to the control group as seen in table 2. Contrary to that, the values of Shore A hardness were increased significantly after 100 hours of artificial weathering (p<0.05) and increased non-significantly (p>0.05) after 200 hours of artificial weathering. While the surface roughness test values were increased significantly after 100 and 200 hours of artificial weathering (p<0.05) as presented in tables 4 and 5.

Table 4: Descriptive statistics, One-way ANOVA, LSD, coefficient of determination (R2) and % of variation values of Shore A hardnedd test

| A | B | C | LSD | |||||||

| (control) | ( after 100 h) | (after 200 h) | ANOVA F- test | P- value | Compared groups | P. values | Sig. | |||

| N | 10 | 10 | 10 | A | B | 0 | HS | |||

| Mean | 42.15 | 44.09 | 44.52 | B | C | 0 | HS | |||

| SD | 0.8922 | 0.8306 | 0.7885 | 22.691 | 0 | C | 0.261 | NS | ||

| Min. | 40.5 | 43 | 43.4 | HS | B | R2 | % of variation | |||

| Max. | 43.3 | 45.7 | 46 | A | C | 0.412 | 41.216 | |||

| B | C | 0.016 | 1.664 | |||||||

| 0.0002 | 0.025 |

Table 5: Descriptive statistics, One-way ANOVA, LSD, coefficient of determination (R2) and % of variation values of Surface roughness test

| A | B | C | ||||||||

| (control) | ( after 100 h) | (after 200 h) | ANOVA F- test | P- value | Compared groups | P. values | LSD | |||

| N | 10 | 10 | 10 | A | B | 0 | Sig. | |||

| Mean | 0.3207 | 0.4268 | 0.4549 | B | C | 0 | HS | |||

| SD | 0.0061 | 0.0096 | 0.0185 | 316.858 | 0 | C | 0 | HS | ||

| Min. | 0.31 | 0.41 | 0.43 | HS | B | R2 | HS | |||

| Max. | 0.33 | 0.44 | 0.48 | A | C | 0.048 | % of variation | |||

| B | C | 0.025 | 4.884 | |||||||

| 0.042 | 2.56 | |||||||||

| 4.284 |

Discussion

Changes in the mechanical and physical characteristics of polymers may result in significant loss in their mechanical and physical properties.22 Impairment in the materials properties may reduce its service life and in turn create the need for its replacement.23 Weathering is one of the methods of testing the polymer properties because the irradiated polymers may undergo structural modifications represented mainly by changes in their molecular weight distribution due to main chain scission, cross-linking and end-linking, and the production of volatile degradation products.24,25,26

In the present study, the specimens were exposed to 100 and 200 hours of artificial weathering, equivalent nearly to 3 and 6 months of clinical use, taking into consideration the climatic conditions in Baghdad city.27,28

Chemically, FTIR spectral could not reveal any chemical reaction between the silicone and the PA-6 particles but this does not mean the absence of any interaction between them. FTIR test is quantitative and qualitative analysis29; this indicates that the amount of the material plays an important role in its detection. The 1% by weight PA-6 fillers is too little to be detected. Hence, XRD analysis was performed to assure the incorporation of the PA-6 fillers within the silicone matrix and forming a 3-D network which is noticed by comparing the XRD pattern of the silicone before and after the addition of the PA-6 fillers (Fig.5).

The increase in the tensile strength (by 13.93%), elongation percentage (by 5.017%) and tear strength (by 1.587%) in comparison to the control group after 100 hours of artificial aging may be due to the enhanced chemical reaction (photo-oxidation) inside the Weather-Ometer that generates free radicals which react with each other and lead to cross-linking that changes the polymer weight distribution and increases the density of the structural network by forming bonds between the existing monomers or chains owing to the increase in the material’s strength value.26,30,31,32 Moreover, PA-6 particles can also be cross-linked reversibly with UV light and temperature inside the Weather- Ometer chamber which results in a change in the physio-mechanical properties of the polymer.33,34,35 while reduction in the same values in comparison to the control group by 0.13%, 10.89% and 2.822%, respectively, and in comparison to group B by 32.83%, 34.222% and 45.292%, respectively, after 200 hours of artificial aging may be as a result of the reaction between the oxygen with the free radicals who were generated as a consequence to photo-oxidation leading to the formation of polymer oxy- and peroxy radicals that result in chain scission affecting the molecular weight distribution and decrease in the density of the structural network by fracturing the bonds , mostly C-H bonds, within the main chain or between two different chains owing to the reduction in the material’s strength value.26,30,31,32

In contrast to the previously mentioned values, hardness and surface roughness values increased in comparison to the control group by 41.216% and 4.884%, respectively, after 100 hours of aging. They were also increased after 200 hours of aging in comparison to the control group by 2.822% and 2.560%, respectively, and by 0.025% and 4.284%, in comparison to group B. The increase in hardness value may be attributed to the continuous silicone polymerization associated with UV exposure during the aging process.36,37 Additionally, the hardness may probably increase as the dose and the duration of radiation increased.38 Another possible explanation, when the polymer molecules absorb the UV light, instability in the polymer structure is promoted. On the other hand, the excess energy may be transmitted from one molecule to another then released into heat or light. During this process, a photochemical degradation takes place resulting in deterioration in the affected molecules and attributing in the increase in the material hardness.14

The result of this study reported an increase in surface roughness; this can most probably be attributed to alteration in the chemical structure of the material as a result of the prolonged exposure to the aging conditions inside the Weather- Ometer. These changes may result in the formation of micro-cracks, and pits on the surface layer of material giving rise to a reduction in the capability of the material to withstand the aging conditions that aggravate all other degradation effects.1 Moreover, the hydrophobicity of the material is an important property relating to the smoothness of the material surface; the hydrophilic character of the amide group PA-6 may give rise to a material with rough surface.39

Conclusions

The following conclusions were reached after taking into consideration the limitations of this study.

The addition of PA-6 micro fillers prevents rapid degradation of some mechanical properties of silicone under aging condition.

Variation in the mechanical properties values’ is directly proportional to the dose and duration of the radiation.

Acknowledgments

Authors wish to thank the dean as well as the assistant dean for scientific affairs of the college of dentistry, university of Baghdad for their kind support in facilitating using the available resources and materials to accomplish this work.

Conflict of Interests

The authors declare that there is no conflict of interests regarding the publication of this paper.

Funding Source

The authors have no funding to report.

References

- Goiato M.C, Pesqueira A. A, Silva D.C.R, Filho G.H & Santos D.D.M. Patient satisfaction with maxillofacial prosthesis. Literature review. JPRAS. 2009;62(2):175-180. DOI: 1016/j.bjps.2008.06.084.

- Haddad M.F, Goiato M.C,Santos D.D.M, Moreno A, D’almeida N. F & Pesqueira A. A. Color stability of maxillofacial silicone with nanoparticle pigment and opacifier submitted to disinfection and artificial aging. Biomed. Opt. 2011;16(9):095004-095006. DOI: 10.1117/1.3625401.

CrossRef - Marafon P, Mattos B. S.C, Saboia A.C. L & Noritomi P.Y. Dimensional accuracy of computer-aided design/ computer-assisted manufactured orbital prostheses. Int. J. Prosthodont. 2010;23(3):271–276. Available at http://www.quintpub.com/journals/ijp/abstract.php?article_id=8083#.WckWkLKx2M8.

- Scolozzi P & Jaques B. Treatment of midfacial defects using prostheses supported by ITI dental implants. Reconstr. Sur. 2004;114(6):1395-1404. DOI: 10.1097/01.PRS.0000138595.86570.3E.

CrossRef - Hatamleh M.M & Watts D.C. Effects of accelerated artificial daylight aging on bending strength and bonding of glass fibers in fiber-embedded maxillofacial silicone prosthese J. Prosthodont. 2010;19(5): 357–363. DOI: 10.1111/j.1532-849X.2010.00584.x.

CrossRef - Udagama A & Drane J.B. Use of medical-grade methyl triacetoxy silane crosslinked silicone for facial prostheses. Prosthet. Dent. 1982;48(1): 86-88. DOI: 10.1016/0022-3913(82)90052-X.

CrossRef - Gunay Y, Kurtoglu C, Atay A, Karayazgan B & Gurbuz C.C. Effect of tulle on the mechanical properties of a maxillofacial silicone elastomer. Mater. 2008;27(6):775-779. DOI: 10.4012/dmj.27.775.

CrossRef - Han Y, Kiat-Amnuay S, Powers J. M & Zhao Y. Effect of nano-oxide concentration on the mechanical properties of a maxillofacial silicone elastomer. Prosthet. Dent. 2008;100(6):465-473. DOI: 10.1016/S0022-3913(08)60266-8.

CrossRef - Zayed S.M, Alshimy A.M & Fahmy A.E. Effect of surface treated silicon dioxide nanoparticles on some mechanical properties of maxillofacial silicone elastomer. J. Biomater. 2014;2014:750398-750405. DOI: 10.1155/2014/750398.

CrossRef - Allah A.J & Muddhaffer M. Influence of Artificial Weathering on Some Properties of Nano Silicon Dioxide Incorporated Into Maxillofacial Silicone. IJSR. 2017;6(5):423-428. Available at https://www.ijsr.net/archive/v6i5/ART20173131.pdf.

- Tukmachi M & Moudhaffer M. Effect of nano silicon dioxide addition on some properties of heat vulcanized maxillofacial silicone elastomer. JPBS. 2017;12(3-4):37-43. DOI: 9790/3008-1203063743

- Rai S.Y & Guttal S.S. Effect of intrinsic pigmentation on the tear strength and water sorption of two commercially available silicone elastomers. J. Indian. Prosthodont. 2013;13(1):30-35. DOI: 10.1007/s13191-012-0174-1

CrossRef - ISO/TR 27628. Workplace atmospheres – Ultrafine, nanoparticle and nano-structured aerosols – Inhalation exposure characterization and assessment. 2007.

- Santos D.D.M, Goiato M.C, Moreno A, Pesqueira A. A, Carvalho D, Dekon S.F & Guiotti A.M. Effect of addition of pigments and opacifier on the hardness, absorption, solubility and surface degradation of facial silicone after artificial ageing. Degrad. Stab. 2012;97(8):1249-1253. DOI: 10.1016/j.polymdegradstab.2012.05.033

CrossRef - Abdullah H.A. Evaluation of some mechanical properties of a new silicone material for maxillofacial prostheses after addition of intrinsic pigmen M.Sc. Thesis, University of Baghdad. 2016;53-58.

- ASTM G154-06, Standard Practice for Operating Fluorescent Ultraviolet (UV) Lamp Apparatus for Exposure of Nonmetallic Materials. ASTM International, West Conshohocken, PA, USA. 2006.

- ISO 37. Rubber, vulcanized or thermoplastic — Determination of tensile stress-strain properties. 2011.

- ASTM D624-00. Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers. ASTM International, West Conshohocken, PA, USA. 2012.

- Al-Harbi F.A, Ayad N.M, Saber M.A, Arrejaie A.S & Morgano S.M. Mechanical behavior and color change of facial prosthetic elastomers after outdoor weathering in a hot and humid climate. Prosthet. Dent. 2015;113(2):146-151. DOI: 10.1016/j.prosdent.2014.09.008.

CrossRef - Fouad M & Moudhaffer M. Effect of Disinfection on Some Properties of Heat-Vulcanized Maxillofacial Silicone Elastomer Reinforced by Nano Silicone Dioxide. JBCD. 2016;28(4):16-21. DOI: 12816/0033205.

- ISO 7619-1. Rubber, vulcanized or thermoplastic – Determination of indentation hardness – Part 1: Durometer method (Shore hardness). 2010.

- Eleni P. N, Krokida M.K & Polyzois G.L. The effect of artificial accelerated weathering on the mechanical properties of maxillofacial polymers PDMS and CPE. Mater. 2009;4(3):35001. DOI: 10.1088/1748-6041/4/3/035001.

CrossRef - Wang L, Liu Q, Jing D, Zhou S & Shao L. Biomechanical properties of nano-TiO2 addition to a medical silicone elastomer: the effect of artificial ageing. Dent. 2014;42(4):475-483. DOI: 10.1016/j.jdent.2014.01.002.

CrossRef - Dootz E.R, Koran A & Craig R.G. Physical property comparison of 11 soft denture lining materials as a function of accelerated aging Prosthet. Dent. 1993;69(1):114–119. DOI: 10.1016/0022-3913(93)90250-R.

CrossRef - Maxwell R.S, Cohenour R, Sung W, Solyom D & Patel M. The effects of γ-radiation on the thermal, mechanical, and segmental dynamics of a silica filled, room temperature vulcanized polysiloxane rubber. Degrad. Stab. 2003;80(3):443-450. DOI: 10.1016/S0141-3910(03)00028-4.

CrossRef - Guo J.H. Aging processes in pharmaceutical polymers. Sci. Technol. Today. 1999;2(21):478-483. DOI: 10.1016/S1461-5347(99)00210-2.

CrossRef - Al-Douri Y & Abed F.M. Solar energy status in Iraq: Abundant or not—Steps forward. Renew. Sustain. Energy. 2016;8(2):025905. DOI: 10.1063/1.4947076.

CrossRef - AL-Riahi M & Al-Kayssi A. Some comments on time variation in solar radiation over Baghdad, Iraq”. Energy. 1998;14(1-4):479-484. DOI: 10.1016/S0960-1481(98)00107-4.

CrossRef - Shaikh T.N & Agrawal S. Qualitative and Quantitative Characterization of Textile Material by Fourier Transform Infra-Red. IJIRSET. 2014; 3(1):8496-8502. Available at https://www.omicsonline.org/peer-reviewed/qualitative-and-quantitative-characterizationof-textile-material-by-fourier-transforminfrareda-brief-review-46115.html.

- White J & Turnbull A. Weathering of polymers: mechanisms of degradation and stabilization, testing strategies and modelling. Mater. Sci. 1994;29(3):584-613. DOI: 10.1007/BF00445969.

CrossRef - Rabek J.F. Polymer photodegradation: mechanisms and experimental methods, New York: Chapman & Hall. 2005;24-25.

- Paravina R.D, Majkic G,Perez D.M.M & Kiat‐Amnuay S. Color difference thresholds of maxillofacial skin replications. Prosthodont. 2009;18(7):618-625. DOI: 10.1111/j.1532-849X.2009.00465.x. Epub 2009 Apr 20.

CrossRef - Aytac A, Deniz V, Şen M, Hegazy E.S & Guven O. Effects of gamma and electron beam irradiation on the properties of calendered cord fabrics. Phys. Chem. 2010;79(3):297-300. DOI: 10.1016/j.radphyschem.2009.08.022.

CrossRef - Tunc D. Synthesis of functionalized polyamide 6 by anionic ring-opening polymerization. Bordeaux. 2014;42-167.

- Pramanik N.K, Haldar R, Niyogi U.K & Alam S. Effect of electron beam irradiation on the kinetics of non-isothermal crystallization of Nylon 66′. JMS-PAC. 2014;51:296-307. DOI: 1080/10601325.2014.882689.

- Santos D.D.M, Goiato M.C, Sinhoreti M.A.C, Fernandes A.Ú.R, Prado D, Ribeiro P & Dekon D C.S.F. Color stability of polymers for facial prosthesis. Craniofac. Surg. 2010;21(1):54-58. DOI: 10.1080/10601325.2014.882689.

CrossRef - Nguyen C.T, Chambers M.S, Powers J.M & Kiat-Amnuay S. Effect of opacifiers and UV absorbers on pigmented maxillofacial silicone elastomer, part 2: mechanical properties after artificial aging. Prosthet. Dent. 2013;109(6):402-410. DOI: 10.1016/S0022-3913(13)60328-5.

CrossRef - Polyzois G.L, Tarantili P.A, Frangou M.J & Andreopoulos A.G. Physical properties of a silicone prosthetic elastomer stored in simulated skin secretions. Prosthet. Dent. 2000;83(5):572-577. DOI: 10.1016/S0022-3913(00)70017-5.

CrossRef - Amin M, Akbar M & Amin S. Hydrophobicity of silicone rubber used for outdoor insulation (an overview). Rev. Adv. Mater. Sci. 2007;16: 10-26. Available at http://www.ipme.ru/e-journals/RAMS/no_11607/amin.html.